Additive Manufacturing

Additive Manufacturing Powder Characterized by High Resistance, Toughness

Böhler distributor, Edro Engineering, highlights Böhler W360 Ampo powder, which after hardening and tempering, achieves high temperature wear resistance, heat resistance and toughness.

Read More3D-Printed Tooling Platform Ramps Up Injection Molding Tooling Capabilities

Addifab and Nexa3D collaborate to bring a novel 3D-printed injection mold tooling platform to moldmakers globally, leveraging faster, cheaper and greener 3D printing.

WatchMetal Powder Advances Additive Manufacturing for Moldmaking

A high-grade metal powder developed by Hasco is offered in two grades and offers optimized particle size, roundness and homogeneity.

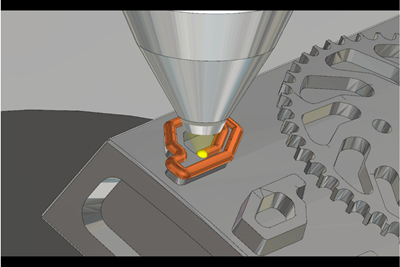

Read MoreRepair, Repurpose Tooling in One Process with Hybrid/Additive Manufacturing

Open Mind Technologies offers an Additive Manufacturing capability option to hyperMILL to support 3D printing/additive processes, such as DED, WAAM and laser powder.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

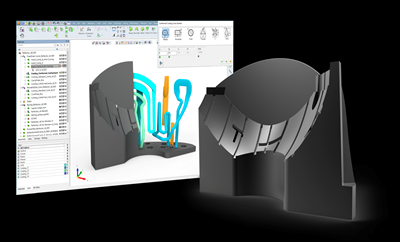

Read MoreEnd-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality

Cimatron works with moldmakers to design and optimize molds with conformal cooling, prepare it for an accurate print and ensure complete post-processing.

Read MoreMold in a Day Technology Slashes Tool Production, Eliminates Supply Chain Headache

Next Chapter Manufacturing says its Mold in a Day additive manufacturing technology slashes the production of tooling down to hours while maintaining the same quality and tolerance standards of conventional molds.

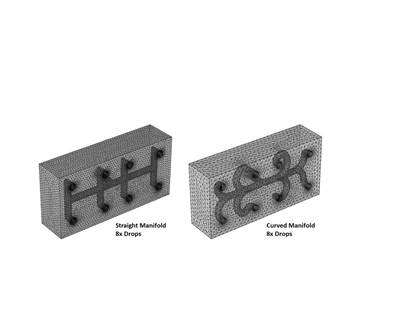

Read MoreGuidelines for Advanced Hot Runner Manifold Channel Design

Recent simulation research highlights the difference between a drilled, straight manifold channel design and a curved channel design produced via additive manufacturing.

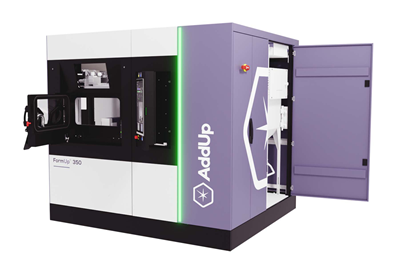

Read MorePowder Bed Fusion Printer Creates Molds with Increasingly Complex Geometries

Global metal additive manufacturing company AddUp Inc. introduces the FormUp 350 powder bed fusion printer, which uses very fine powders for the development of complex molds and industrial parts.

Read MoreCutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

Read More