Hot runner manifold channel design is essential for the operation of an injection mold, impacting change-out time, part quality and even the number of possible drop locations in the mold. The key to advancing manifold design is having the ability to manufacture and implement curved channels in blocks of steel.

Cross-drilling and plugging a block of steel produces the simplest manifolds. Advanced manifolds may use brazed plug inserts to round internal corners or two-piece brazed manifolds to achieve curved internal channels without plugs. However, plugs are a complicated solution that can still leave drag spots. Brazed plates can be successful, but they have limited size and potential quality issues because of the weakness of braze joints (which are basically a metal “glue”). Manifolds are typically subject to the hottest temperatures and the highest pressure of either the mold or the hot half, making steel strength critical for maintaining the mechanical integrity of the hot half.

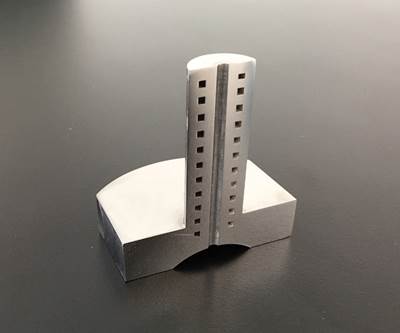

Curved manifold channel design produced by metal additive manufacturing (AM) is a new method capable of achieving a better balance of fill across drop locations (or equalized residence time of the polymer), according to a recent research project by Oak Ridge National Laboratory (ORNL) and HTS International Corp. with the simulation effort headed by Dr. Prashant K. Jain and Dr. John A. Turner of ORNL. The findings in the research mean faster color changes, improved hot runner system stability and reduced pressure requirements. Hybrid metal additive manufacturing equipment has made it possible to produce smooth internal surface finish for H11, H13 and 420 SS variants of components. Hybrid AM involves a machining step during layer buildup, which offers superior surface finish to the standard printed finish from power-bed processes.

To date, metal additive manufacturing has produced advanced, curved manifolds H11 (1.2343) at a footprint of 600 millimeters by 400 millimeters. This is three to five times larger than the size of previous generations of curved manifolds produced using brazing technologies.

Curved manifold channel design produced by metal additive manufacturing is a new method capable of achieving a better balance of fill across drop locations.

The R&D began in 2017 in an effort to understand and publish guidelines for proper hot runner manifold channel design. These guidelines are relevant for hot runner manifold construction, independent of the method of manufacturing. Some of the basic findings are summarized here to showcase the considerable difference between a drilled, straight manifold design and a curved channel design.

Assumptions. This research was performed under the assumptions that polypropylene melts at uniform temperature, which is equal to 250°C (plus or minus 30°C) and that the polypropylene had a Newtonian, laminar flow. The pressure boundary was at an inlet of 10 kilopounds per square inch, and the research was performed using an isothermal steel manifold.

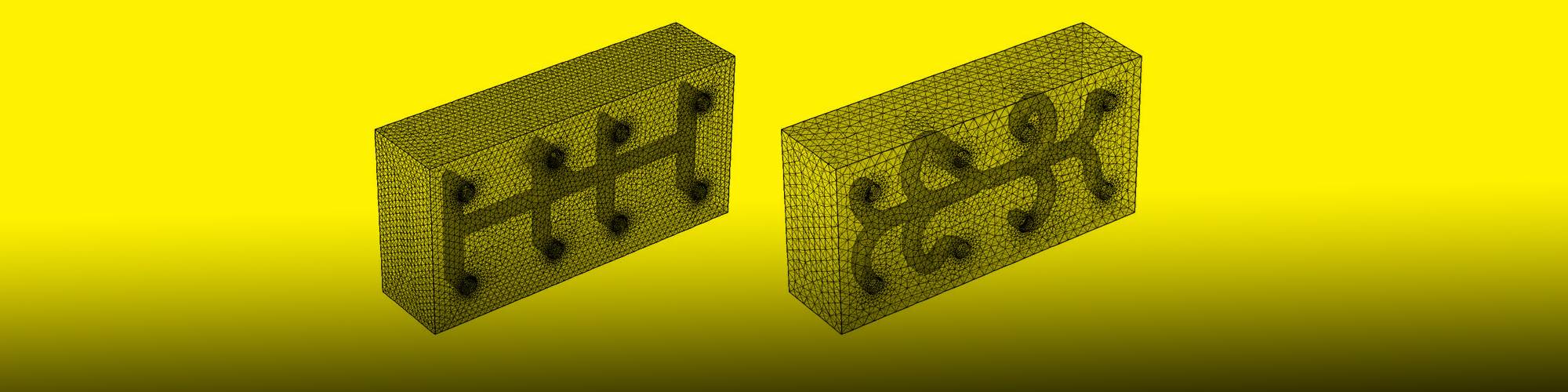

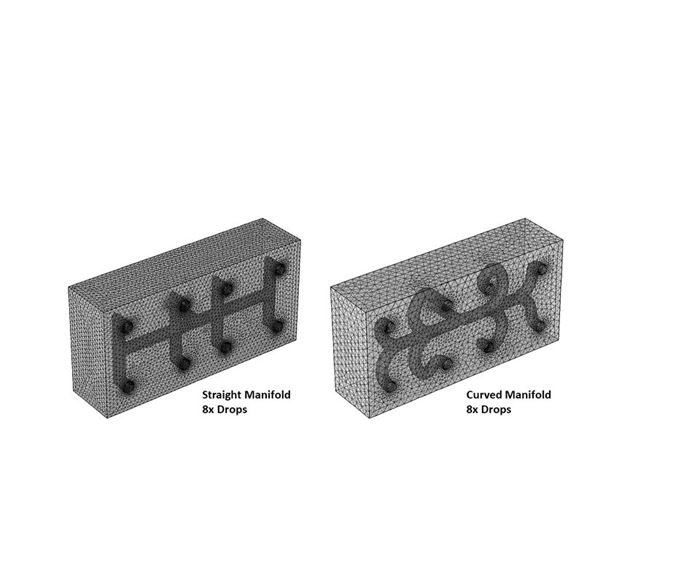

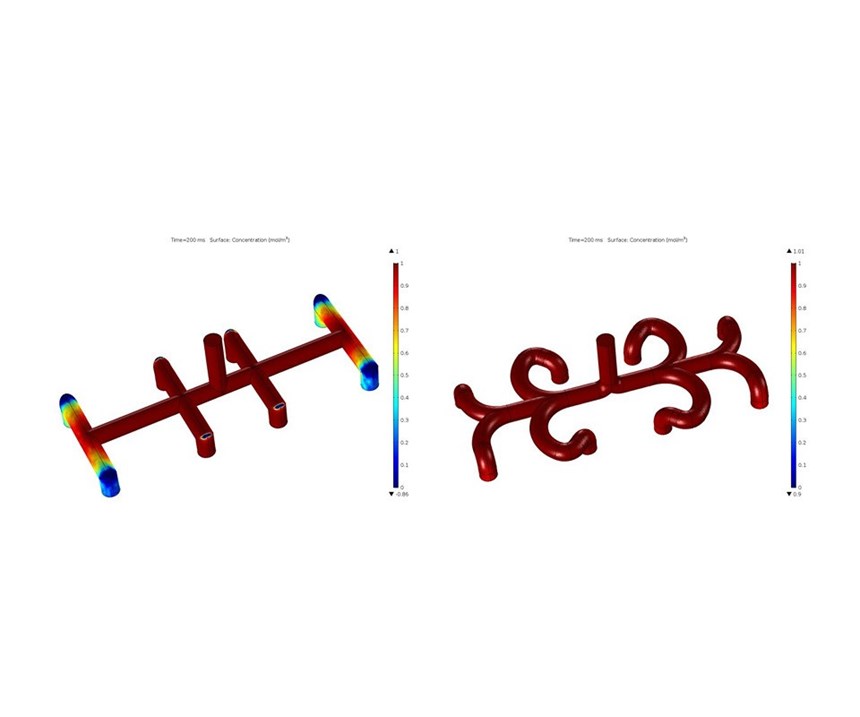

The curved manifold (see Figure 1) was designed for equal flow channel length. Other parameters could be optimized, including pressure drop and residence time. The results of the simulations were significant: residence time (or the time that the polymer spends in the manifold channels) was nearly equalized along the different flow paths. The residence time was cut from 400 milliseconds to 200 milliseconds in the outer channels (see the labeled positions 1 and 4 between the graphs in Figure 2), while the residence time was increased from 100 milliseconds to 200 milliseconds in the interior channels (see the labeled positions 2 and 3 between the graphs in Figure 2).

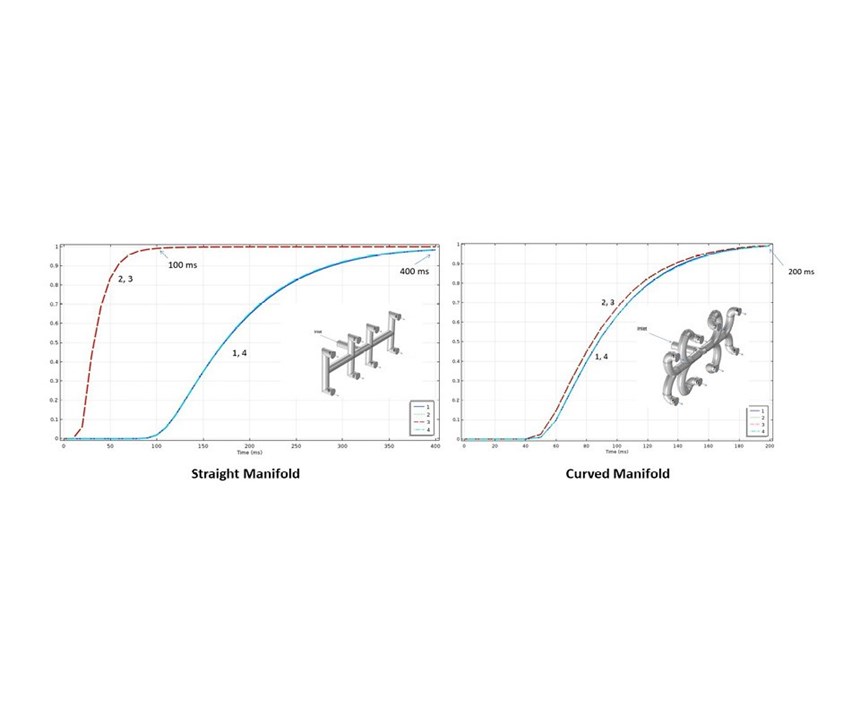

A look at the normalized, surface-concentration profile further validates the equal filling profiles in the curved manifold compared with the conventional manifold (see Figures 3 and 4). While the cases shown represent two extreme ends of the manifold design spectrum, the benefits of removing constraints on the shape of the manifold channels are clear. For multi-cavity molders, new production capabilities with metal AM can enable the design of higher-density injection gates and can simplify the manifold stack. For single-cavity molders (as in many automotive molds), these new capabilities enable the strategic placement of drops in complex arrangements.

These benefits occur because patterns are developed without regard for intersecting cross-drill patterns, and curved channels can add path length into a reduced footprint for drops closer to the manifold inlet. Curved channels also reduce the path length for drops located further from the manifold inlet. Lastly, curving channels in a single manifold body reduce stack height instead of having to stack symmetrically drilled manifolds to achieve uniform channel length in high-volume tools.

About the Contributor

Dr. William Sames, Ph.D.

Dr. William Sames is CEO of HTS International Corp.

Related Content

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreRead Next

Cooling of the Sprue

Using conformal cooling in sprue bushing design may be one solution for reducing cycle times.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More