Additive Manufacturing

Die-Cast Mold Conformal Cooling Achieved Through Hybrid Multi-Material 3D Printer

The DMG MORI Lasertec 65 DED hybrid combines 3D printing with milling to manufacture cooling channels in a single setup.

Read MoreMulti-Laser Powder Bed Fusion 3D Printer Supports Complex Mold Building

Using its FormUp 350 system, AddUp, in collaboration with Siebenwurst Group, improved the conformal cooling channels for a mold slide.

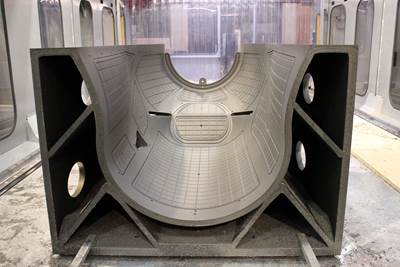

Watch3D Printing Systems Demonstrate Large-Scale Mold Building

CNC machine and large-scale large-scale additive manufacturing machine producer Thermwood highlights partner projects that advance mold production capabilities in the aerospace and defense industries.

Read MoreCAD/CAM Software Generates Unique Additive Tool Paths for Mold Cooling Channels

The Open Mind hyperMILL Additive Manufacturing solution offers a variety of additive/hybrid functionalities, including toolpath strategies for designing intricate conformal cooling in a multi-axis machining setup.

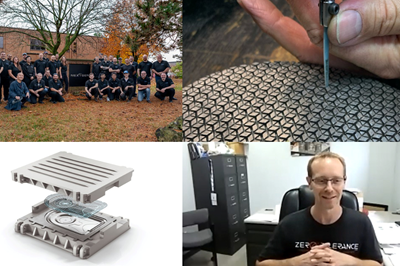

WatchWestec Plastics 3D Prints Mold Inserts Using TrueShape Technology

Mantle’s metal 3D printing enabled Westec to rapidly respond to changing customer demands, quickly produce prototype H13 mold inserts and keep design and development on track.

Read MorePrecision Metal 3D Printing Technology for Mold Manufacture

Mantle’s P-200 3D printer, combined with the TruShape process, achieves high-performance part production with shorter lead times and lower costs.

Read MoreNext Chapter Manufacturing Expands Into Medical Industry, Initiates NXCMED

Additive surgical company will deliver surgical device solutions, such as implants and complex surgical devices, through disruptive design and 3D printing technologies.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read More3D-Printed Tooling Workflow Achieves Complex Part Prototyping

Addifab freeform injection molding (FIM) simplifies design and delivery of injection-molded test parts through scaled production of 3D-printed mold cores and cavities compatible with any molding feedstock.

WatchPTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

Read More