Additive Manufacturing

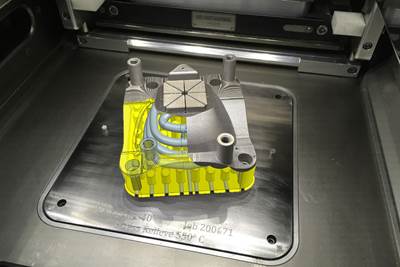

How to Use Hybrid Additive Manufacturing

A look at directed energy deposition (DED) and powder bed fusion (PBF) additive technologies for moldmaking applications.

WatchWestminster Tool Awarded $100,000 Grant for Additive Technology

Westminster Tool joins six manufacturing companies in CT as recipients of the latest Additive Manufacturing Adoption Program (AMAP) grant, highlights its importance to injection moldmaking.

Read MoreZeiss, ORNL Introduce Fast, Automated Print Parameter Qualification at RAPID + TCT 2021

Zeiss ParAM (Parameter for Additive Manufacturing) comprehensively evaluates a set of parameters in less than 12 hours, reduces build failure rate, cost per part and improves reliability.

Read MoreRenishaw Partners with Connecticut Center for Advanced Technology

Renishaw provides industrial metrology and additive manufacturing equipment to the Connecticut Center for Advanced Technology (CCAT) to implement digital technologies and prepare new talent for the industry.

Read More2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

Watch3D Printing Speeds Prototyping and Shifts Talent to Production Tooling

A digital approach to prototyping using 3D-printed tooling accelerates product development and frees up mold builders for production tooling work.

Read MoreExploring AM Powders for Tooling

More options in AM tooling materials exist today that provide properties for crack resistance, thermal conductivity and heat treatment.

Read MoreWEBINAR: Tool Steel Demands and Enhancements

Pressurized electro-slag refining and powder metal production techniques remove impurities when producing highly alloyed stainless steel grades specifically for moldmaking. Listen to this free webinar to learn about current trends in the plastics industry, next-generation stainless tool steels, production techniques and additively manufactured parts and components.

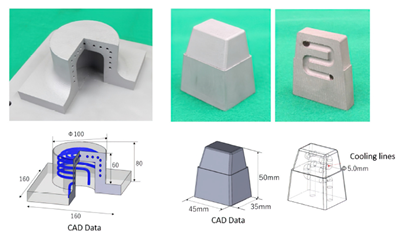

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read More2021 Sourcing & Technology Guide: Additive Manufacturing

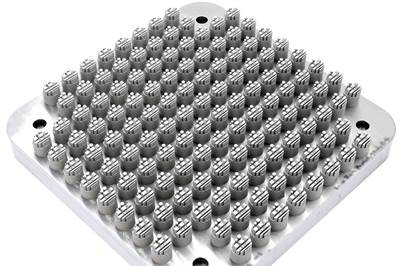

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read More