Powder Bed Fusion Printer Creates Molds with Increasingly Complex Geometries

Global metal additive manufacturing company AddUp Inc. introduces the FormUp 350 powder bed fusion printer, which uses very fine powders for the development of complex molds and industrial parts.

Photo Credit, all images: AddUp Inc.

AddUp Inc. is a global metal additive manufacturing (AM) OEM, providing industrial-scale metal 3D printers. The company evolved from a partnership between tire manufacturer Michelin and Fives for a laser powder bed fusion (L-PBF) machine to build tire mold inserts and industrial parts with quality, accuracy and repeatability.

AddUp launched the FormUp 350 New Generation powder bed fusion (PBF) machine in 2021. This machine can reportedly create molds with increasingly complex geometries with internal passages that cannot be achieved with conventional manufacturing processes. The FormUp 350 enables the use of very fine powders (5-25 μm), which when coupled with a roller recoating system, provides users with a support-free production of cantilevered parts down to 10º, and achieves surface finishes of sub-10 μm arithmetic roughness (Ra).

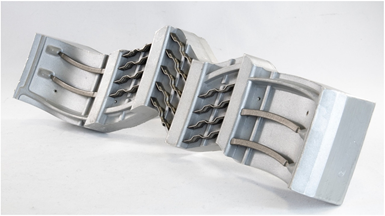

Tire mold produced by AddUp.

According to AddUp, the FormUp 350 also offers an autonomous powder module that provides all the functions of powder management. It provides a constant supply of powder, without interrupting production, regardless of the quantities to be produced. The modular design of the FormUp 350 machine also allows each manufacturer to configure the machine according to their specific needs, offering users a scalable option to increase their level of productivity while guaranteeing user safety.

Related Content

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Building Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.