Additive Manufacturing

Taking the Plunge: AM Resources for Mold Builders

Additive manufacturing is a trending manufacturing process for a range of industries, least of all moldmaking, and its implementation has demonstrated a host of benefits.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read More2022 Sourcing & Technology Guide: Additive Manufacturing

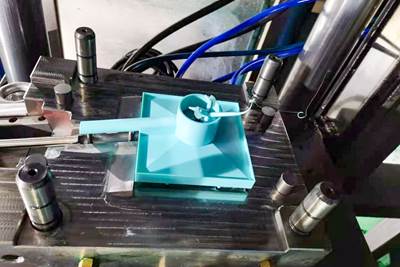

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read MoreFrom Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreHybrid Metal 3D Printer Redefines Mold Component Production

Matsuura Machinery is highlighting several of its high-speed, Industry 4.0 five-axis VMC and HMC machines at IMTS 2022, as well as its LUMEX metal 3D printing expertise for moldmakers.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

WatchTechnology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

WatchNew Metal 3D Printing System Accelerates Mold Insert Production

Faster tooling production, including the manufacture of precision metal mold inserts, can be achieved via Mantle’s new metal 3D printing technology.

Watch3D Metal Printing Adoption Enables Rapid Design Changes, Internal Feature Inclusion, Quality Components

Xact Metals’ 3D printing technologies and services are offered for quick, efficient and cost-effective moldmaking and tooling production.

Read MoreLights-Out Metal 3D Printer Minimizes EDM Needs for Moldmakers

The Matsuura LUMEX series boasts both forming and milling capabilities in one unit, achieving highly accurate mold component production, with the ablity to integrate conformal cooling and porous venting.

Watch