End-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality

Cimatron works with moldmakers to design and optimize molds with conformal cooling, prepare it for an accurate print and ensure complete post-processing.

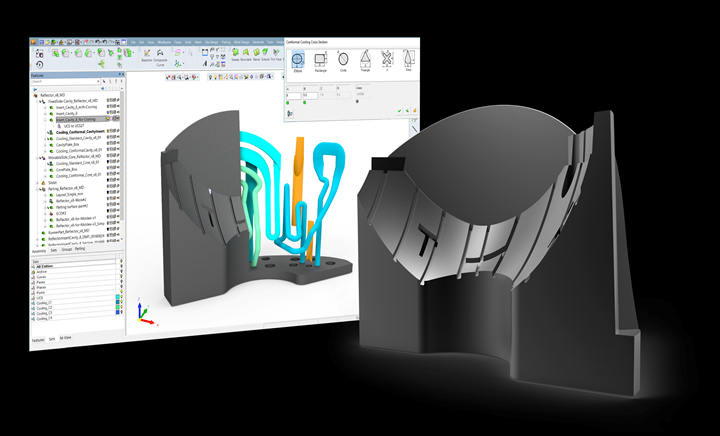

Photo Credit: Cimatron

Cooling is a critical process for plastic injection molds, affecting both cycle time and final part quality, Cimatron notes, but is especially challenging for complex parts when using traditional drilling and milling methods. To avoid longer cycle times, warpage and sink marks on the part, the company presents its intelligent conformal cooling channel design for faster cycle times, better part quality and a more efficient cooling process.

Cimatron’s end-to-end solution reportedly enables moldmakers to detect areas that would benefit from conformal cooling channels, from using its dedicated toolset to design the mold with an optimal combination of conventional and conformal cooling channels, to preparing the mold component for 3D printing and post-processing. Cimatron’s conformal cooling solution is also available as a standalone seat that can work alongside other mold design systems.

According to Cimatron, the car reflector headlight example above demonstrates how its conformal cooling solution reduces injection molding cycle time and significantly improves part quality including:

- Cycle time reduction by 17% (from 40.3 sec to 33.4 sec).

- Warpage reduction by 62%.

- Part temperature deviation reduced by 73%.

- Sink mark affected areas reduced by 50%.

Related Content

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.