MMT Blog

Top 10 Lessons Learned in Moldmaking over the Past 10 Years

Top 10 Lessons Learned in Moldmaking

Read MoreCoatings Enhance Tool Life and Performance

Surface coatings have evolved over the past decade—offering improved operation uptime, greater consistency and higher part quality

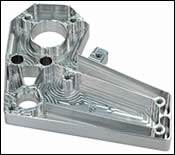

Read MoreMoldmakers Are Increasing Business And Profits with Aerospace Work

Expertise in metal fabrication and machining creates opportunities for mold shops seeking diversification.

Read MoreMaking Sense out of Machine Tool Specifications

Are you doing an accurate comparison when you’re evaluating machine tools?

Read MoreRe-defining Precision

It’s important not to limit the definition of precision to one in particular, but instead expand the definition to three unique precision types: micro precision, ultra precision and nano precision.

Read MoreIntelligent Machining Software to Increase Surface Finish and Productivity in Mold Mfg

Progress in the realm of software offers moldmakers the opportunity to maximize the potential of their machining processes when it comes to maintaining extremely high surface finishes.

Read MoreCAD/CAM’s Come a Long Way

The past decade has seen the CAD/CAM industry explode when it comes to its efficiency, sophistication and speed.

Read MoreFive Key Factors Affecting a Shop’s Ability to Innovate

What does it really mean to be an innova-tive company and how does a shop know if it is innovative? The factors that must be in place to support innovation are not a mystery. Companies that rely on ‘innovative thought’ to advance their product devel-opment, sales and customer service processes must be sure that they close any gaps in their capacity to encourage and support this breakthrough thinking.

Read MoreGas Permeable Mold Steel

The use of venting material in appropriate areas can eliminate gas buildup, reduce injection pressure, lower cycle times, gloss levels and substantially reduce scrap and reject rates.

Read MoreTwelve Techniques for Managing Moldmaking Design Data Effectively

Mold manufacturers can address time, cost, quality and global communication challenges by using 3-D CAD software in combination with an integrated product data management system.

Read MoreCompensating for Thermal Expansion to Maintain Part Accuracy

Moldmakers, who must consistently produce very accurate and precise molds, need to learn how to overcome and work with thermal expansion.

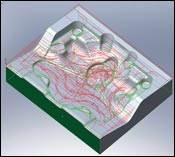

Read MoreSoftware Enhances Advancing Technologies

CAD/CAM’s improved features and new capabilities—combined with the latest in technologies like high speed and five-axis machining, new cutting tools and 3-D technologies—allow moldmakers to achieve the highest quality in the shortest time.

Read More