Coatings Enhance Tool Life and Performance

Surface coatings have evolved over the past decade—offering improved operation uptime, greater consistency and higher part quality

Using surface coatings on molds offers numerous advantages—including longer tool life, improved tool performance and less mold maintenance needed. The last decade has seen major improvements and enhancements in surface treatment technologies.

Industry Changes

Dwayne Douglas, Product Manager Mold & Dies, Oerlikon Balzers Coating USA Inc. (Rock Hill, SC), notes that changes in the surface treatment industry can be attributed to growth in engineered resins in different markets like automotive due to fuel economy mandates as well as post consumer products allowed in the manufacturing of caps/closures. “Their cost of manufacturing has risen and steel costs have gone through the roof,” he states. “So the call for surface treatments for manufacturing while being cost cutting and offering a better bottom line, has increased.

“On the side of surface solutions, the competition has grown,” Douglas continues. “There are more and more companies entering the market to provide this service. There are a lot of surface coatings to choose from—from platings, PVD and PACVD. Each market (e.g. automotive, consumer goods) face their different challenges with resins that have to provide more. For example, there are engineered resins that are meant to be lightweight and rigid enough for the new gas efficient automobiles. Or there are consumer goods that now have a percentage of post consumer products that now weigh in on preexisting molding operations. Surface coatings must be able to keep up with the ever-changing demands for the molders.”

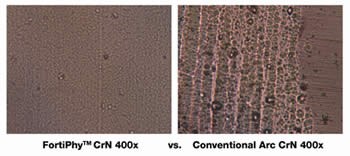

According to Dave Bell, President, Phygen Coatings, Inc. (Minneapolis, MN), advances in surface treatment processes have improved operation uptimes, minimized the use of spray releases, and enhanced the quality of parts since newer coatings offer greater consistency. “The newer coatings aren’t as thick and don’t crack or peel,” Bell explains. “Because of the long life most coatings now have, many coatings are in place years later. Additionally, the latest coatings are dense and homogenous.”

Harry Raimondi, Technical Services Manager, Bales Mold Service (Downers Grove, IL), adds that more customers are looking for protection from glass- and mineral-filled compounds in their coatings. “They also are looking for lubricity to reduce cycle times and release of the newer overmolded compounds used today,” Raimondi emphasizes, “as well as coating build-ups to reduce wall stock on existing tooling—resulting in monetary savings.”

Product Line Changes

In line with advances in tool steels, surface treatment providers have fine-tuned their own offerings. “We have had to adapt to more frequent use of materials in mold manufacturing, such as alloys and variations to them,” Bales Mold Service’s Raimondi states, “as well as some stainless steels—the most challenging of them being ‘unknown’ foreign steels. Investing in x-ray equipment for steel analysis and inspection has become more important and vital to the quality assurance and the on-time delivery demands. We also are providing more choices of specific coatings and their uses, combined with a wider variety of base finishes as well as the ability to analyze detailed SPI finishes.”

More molders are opting for lower temperature coatings, according to Douglas of Oerlikon Balzers. “Once upon a time with the PVD processes, the coating temperatures made it difficult for molders to always rely on the coatings to work on a vast majority of their parts,” he says. “If the cavities were inserted, molders had to go with a lesser proving surface treatment that didn’t always work as good as a PVD process, but was safer for the mold steel. In the future, we will see coatings applied at lower temperatures so that molders will not have the guesswork on the process.”

Phygen has developed a proprietary technology that applies exactly the coating thickness its customers request. “This is a significant breakthrough because we can actually deliver exactly that prescribed coating thickness to our customers,” Bell says. “Another significant development is coatings that are able to be removed in case a mold needs to be repaired—with no damage to the tool.”

Surface treatment providers also are shortening turnaround times. “The leadtimes that tooling can be out for surface treatments also have decreased,” adds Oerlikon Balzers’ Douglas. “No more can tooling afford to be out for over a week to be processed. Tooling now can at most only be out for a couple of days. The days of having huge inventory in order to gauge process time is over.”

“We have turned jobs around in one day,” Phygen’s Bell says. “The precision of applications has been enhanced as well as the speed at which the service is delivered. We find that fast service is a key driver in making sure that the investment that these mold are is maximized for our customers.”

Future Challenges

Douglas of Oerlikon Balzers sees a number of future challenges facing this industry. “The increasing legislation on consumer safety, oil prices and changing political landscape will affect business,” he notes. “The population growth and the availability for countries and more people to purchase goods will continue to rise. Will the Asian cost of manufacturing even out? I think that the plastics market will continue to grow also with surface coating technology. I think you will see smoother coatings and coatings geared toward more engineered resins.”

The need for environmentally green surface solutions also will increase. “Surface coatings in the future cannot have a negative impact on the environment around us,” Douglas maintains.

According to Bell of Phygen, coatings will continue to improve—and find greater appeal with users. In agreement is Raimondi of Bales Mold. “I believe the communication and use of the latest technology between moldmakers, molders, and their vendors to be extremely important,” he explains. “The understanding of the needs of both the vendor and the mold shop will be essential to their combined success. For example, the mold shop needs to understand what the plater and polisher need in regards to plastic being molded and its final finish, steel type and the use of highlighted detailed prints, etc. The plater and polisher need to understand the timeline for mold completion and why it may be necessary to make changes to manpower and time of day shifts and availability 24/7 in order to accommodate mold shops’ requirements.

“The moldmaking industry no longer has any luxury of a delivery time in days,” Raimondi adds. “We are now into what ‘hour’ of what day can you complete this job.”

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

Using TiN Coatings to Protect Your Knock-out/Ejector Pins

Proper surface treatments for enhancing corrosion resistance of mold components in molding situations.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More