Gas Permeable Mold Steel

The use of venting material in appropriate areas can eliminate gas buildup, reduce injection pressure, lower cycle times, gloss levels and substantially reduce scrap and reject rates.

Many of you have probably heard of self-venting or gas permeable mold steel, but are not totally familiar with it. Gas permeable mold steel is a sintered, pre-hardened to 35 HRc material with porosity in the range of 20 to 30 percent by volume. A system of interconnected micron-sized pores is dispersed throughout the material.

Benefits

By using this venting material in appropriate areas, the molder can eliminate gas buildup, reduce injection pressure, lower cycle times, gloss levels and substantially reduce scrap and reject rates.

Eliminates Trapped Gas Problems

The benefits molders derive from using gas permeable mold steel include the elimination of trapped gas problems that occur in inadequately vented areas within the mold. Frequently it is difficult, if not impossible, to provide adequate venting in these hard-to-mold areas. Traditional methods of venting—such as parting line vents, vent plugs and pins—often do not provide sufficient surface area to accommodate the large volumes of gases that can be generated. By inserting gas permeable mold steel, you provide a location-specific method of venting gas in a targeted area. Since it is 25 percent air by volume, one-fourth of the surface area becomes a vent. The larger the surface area of the piece installed, the greater the venting capacity.

Prevents Burning

Burning is a condition caused by compressed gasses trapped by the flow of molten resin in a cavity pocket. By using this venting mold steel, gasses are permitted to evacuate through the steel to the outside atmosphere, thus eliminating the burning condition as seen in Figures 1a,b.

Prevents Knit Lines

Minimizing or eliminating flow and knit lines is an additional benefit. Knit lines occur at points where resin flows converge after molding around an obstruction or protrusion within the mold, usually away from the gate area. There are two primary reasons for this occurrence: (1) failure of resin to sufficiently fuse due to the drop in temperature after flowing over long distances and (2) presence of residual air at the resin flow convergence point at the cavity obstruction, prohibiting the proper fusion of the flows. The permeability of this venting mold steel prevents defects arising from residual gases normally trapped inside the mold cavity. Also, using this material reduces back pressure and improves the flowrate, allowing the resin flows to merge while still hot.

Reduces Cycle Time

Because of the reduction in back pressure within the mold, the plastic fills the cavity faster, thus allowing for reductions in temperatures, which shortens cooling and cycle times.

Eliminates Shrink

Trapped air bubbles between the resin and mold steel surface can cause shrinkage or sink that shows as a ripple in the otherwise straight plastic surface. Using gas permeable mold steel on the trapped air side of the cavity will eliminate shrink in most cases.

Eliminates Short Shots

Short shot is another condition caused by too low of an injection pressure, or trapped gases, in pocket areas of the cavity. This results in the part not being completely filled out. Gas permeable mold steel reduces back pressure; therefore, less injection pressure is needed, and because it vents trapped gases, both causes of short shots are eliminated.

Enhances Part Appearance

Webbed, ribbed and other difficult-to-fill, thin-walled designs are greatly enhanced and cosmetically defined using gas permeable mold steel in the mold. Molding high detailed, thin-walled and aesthetic parts is easily accomplished with reduced back pressure and added venting.

Reduces Gloss Levels

When using this venting steel as a cavity in an injection mold, the air typically trapped between the cavity and the resin (causing a gloss to show on the part) is allowed to escape through the pores, thus leaving a dull matte finish. This often eliminates the need for costly secondary spray painting operations (see Figures 2a,b).

Simplifies Tool Design and Reduces Cost

When back pressures, injection pressures and cycle times are lowered, fewer drops are needed to assure proper filling of the cavity. Lowering the number of drops needed to fill a cavity simplifies design while saving tool costs. In some cases the entire hot runner manifold is eliminated.

Machining and Polishing

Gas permeable mold steel can be machined by conventional methods using cutoff saws, end mills, grinders, EDM, stoning, etc. It is important to remember that this material is honeycombed with thousands of microscopic holes, which are affected by metal removal. Oil coolant is recommended.

Grinding and milling closes the pores of this porous steel. EDM is the best way to re-establish permeability. EDM will burn away the metal fragments that are crushed over the pores by milling and/or grinding. Because of its powdered metal origin, when using a wire EDM, it is important to increase the wire speed about 10 percent to prevent arcing from the particles produced. Because a wire EDM machine uses water, the insert must be dried in an oven after EDM, or rust and pore closure will ensue.

Design Guidelines

The following guidelines should be considered:

Resins Used

Depending on the emissions or gas residue given off during the molding process and flash point of the resin, the molder will have to evaluate whether to use 7- or 20-micron pore size. Resins such as ABS, polypropylene, soft type PVC, polyethylene, acrylic, polyurethane, and styrene work very well with a 7-micron (.0003") pore size. For low viscosity or talc-filled resins, it may be necessary to have an automated system reverse the airflow after each shot to purge the impurities from the pores. Rigid PVC resins will work, but only until the corrosive gasses close the pores. This can still be a feasible method if disposable inserts are used. The 20-micron pore size (.0008”) will vent about 20 percent more gas than the 7 micron pore size.

Surface Finish Requirements

Since most applications can be addressed using inserted pieces on the core side, an EDM finish is acceptable and will vent better than any other surface finish. Should EDM be impractical, after EDM a stoned surface will provide the next best venting surface. The 7-micron pore size provides the best finish. It is important to remember that if the venting steel is used on the cavity side of a mold, the gloss level will be severely reduced (from #9 to #3 with PP), so matching should be considered.

Cleaning, Maintenance and Resin Removal

There are two times cleaning must be performed to gas permeable mold steel: (1)when the tool shop has prepared the insert or cavity. The material is 25 percent air by volume and the cutting fluids will displace the air, thus filling and clogging the pores. After the permeability has been restored by EDM, the venting surface and steel should be professionally cleaned, due to the dangerous nature of the cleaning process; and (2) after the insert or cavity has been in operation and film, a thin layer of mold release agent, resin residue, shop oil or any other contaminant has partially or totally blocked the air flow.

Availability

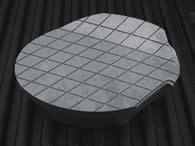

Gas permeable mold steel is available in rounds, rectangles, pre-manufactured core pins, ejector pins, precision ground press in type pins, and if data is available, finished inserts can be supplied (see Figures 3a,b,c).

Conclusion

The age-old venting problems that have faced molders for years can be solved using gas permeable mold steel. Better mold cavity venting adds many benefits from reduction of scrap to better cycle times. Whether it is a retrofit or engineered into the tool from the start, this material adds value to all molds.

Related Content

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreReliable, Efficient 3D Printer for High-Quality Tool Steel Components

The updated TruPrint 2000 underscores Trumpf’s focus on the tool and die industry, including a larger, square build plate and various features to ensure high quality and mass production.

Read MoreVIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreRead Next

Cost Savings for Mold Materials: Consider the Details

Ways to reduce costs that are not related to the price per pound of the mold material.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More