MMT Blog

Polishing Process: Micro Machining Process

MMP, which stands for micro machining process, is a proprietary superfinishing method for metallic parts that delivers consistent, repeatable results using a finely controlled automated process.

Read MoreHow to Choose the Right CNC Router

With moldmaking the focus is on injection molding or other mold types that use wire EDM or CNC machining centers to create the mold components. Your typical machining center weighs several tons and has a relatively small working envelope compared to a CNC router. The mill’s massive construction lends itself to machining rigid materials with very tight tolerances. While this type of CNC is suited for injection molding components, it isn’t always the ideal tool for the job when we broaden our scope of moldmaking and the current opportunities in the marketplace

Read MoreSpecialty Mold Design/Build Reaches New Markets

A fast-growing molding technology results in high quality and reduced production costs for molders. Learning how to design and build molds for this process can expand your capabilities.

Read MoreMold Design Tips for Automation

Automation suppliers can assist mold manufacturers with proper mold design and engineering before cutting steel for new molds. Hot runner molds, cold runner molds, box filling, insert molding, stack molds and multi-component molding are areas that can be built and managed more inexpensively, reliably and simpler.

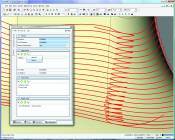

Read MoreSimplified Approach to Complex Five-Axis Machining

As multi-axis machine tools become more complex, CAM software systems must provide a more elegant way to program them.

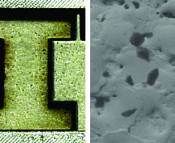

Read MoreElectrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

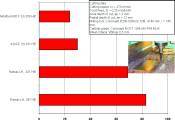

Read MoreCycle to Hit Bottom in the First Half of 2009

38.6 Total Mold Business Index for December 2008 The total Mold Business Index is a weighted average of the sub-indices for new orders, production, employees, backlog, exports and supplier deliveries.

Read MoreDevelopment of a New Mold Base Stainless Steel

Due to the intensive machining practices that must be performed on mold bases, if machining time and costs can be reduced, significant savings can be realized. A premuim free machining stainless holder steel has been developed that has optimized chemistry and processing, which lead to greatly improved machinability as well as other important properties.

Read MoreMoldmaking Skills Give Mar-Lee a Business Boost

Molder taps tool building skills to maintain double-digit growth in high end of the market.

Read MoreAutomating from Quote to Cash

Shop floor automation tools have the ability to take the concept of the interconnected shop to the next level—giving mold manufacturers technology to transform their business, enabling them to expand into new markets and new opportunities.

Read MoreKicking the Can Down the Road

I recently had two seemingly unrelated experiences that gave me an interesting perspective about the current economy, and machine shops in particular. In early December, I was invited to attend a conference call with a group of economists. As they were discussing the condition of the Medium Three automotive companies, one of them said that he wasn’t surprised at all that they were seeking relief (a bailout) in the form of government-backed loans.

Read MoreBuilding a Better Mold

A look at mold performance and maintenance issues through a few simple reports in the right sequence will allow you to drill down into what the issues are really costing you.

Read More