MMT Blog

Using ERP for Better Decision-Making

It has become more essential to know exactly what is going on in your business—not last year, not even last month—but at this very moment.

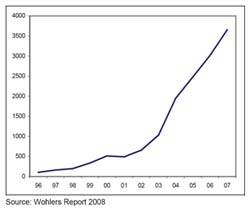

Read MoreThe Impact and Evolution of Additive Fabrication

SAn executive summary of the annual Wohlers Report that provides quantitative and qualitative analysis on the additive fabrication industry worldwide.

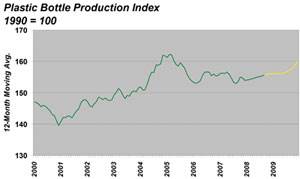

Read MoreSustainability Raises the Stakes for Mold Performance

OEM demands for lightweight packaging are creating design challenges for toolmakers.

Read MoreTrends in Hot Runner Technology

Quality, performance, maintenance and flexibility are driving today’s hot runner technology.

Read MoreThe Realities of Aluminum Tooling

Using aluminum tooling instead of traditional tools steels reduces cycle time and costs, but requires up-front, open communications between moldmaker, molder, material supplier and hot runner manifold supplier.

Read MoreChicago Mold Engineering: “Head”ing Into the Future

With continued focus on its automotive headlamp reflector molds niche, CME relies on technology and equipment advancements to “drive” success.

Read MoreTop 10 Things You Didn’t Know About Moldmaking Before You Entered The Field

December 2008 Top Ten List

Read MoreCAMM: Molding a Future for its Members

The last 10 years have been ones of tremendous growth for the Canadian Association of Moldmakers (CAMM).

Read MoreAn Addition to the Family

MoldMaking Technology was reunited with its sister publication Time-Compression Technologies this past October when it was acquired by Gardner Publications, Inc.

Read MoreTime to Engage

This AMBA event brought together the highest number of mold manufacturing participants the group has seen.

Read MoreSpecialization and Automation Give Matrix an Edge on Competitors

Mold shop’s focus on high-tech capabilities and full-service operation earns it a niche in precision tools.

Read More