MMT Blog

Hot Runner Repair and Maintenance Training

Successful hot runner repair requires a higher level of precision, understanding and accuracy that can only be accomplished in a systemized approach that utilizes accurate documentation of the critical elements of manifold work.

WatchMoldMaking Matters: Your Career Can Make a Difference

Watch the Video: This recruitment tool highlights careers in moldmaking and is designed to attract the next generation of workers.

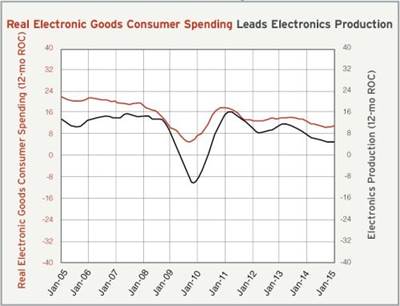

WatchElectronics and Consumer Goods

Electronics poised for a rebound; consumer goods production also should improve in 2015.

Read MoreA Low-Maintenance Approach to Mold Care

Molds are subjected to a variety of strains during the molding process. For them to function as they were designed to and consistently produce quality parts, a regular schedule of maintenance is required.

Read MoreFlexible High-Speed Mold Machining

Use this planning guide to identify the right double-column machining center to fit your mold machining needs.

Read MoreFlexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

Read MoreSimplify Mold Machining

Use true five-axis simultaneous machining for your molds and inserts.

Read MoreHot Manifold Repair: What’s so Tough about it?

Maintaining a typical hot runner system takes mold maintenance skills to the next level.

Read MoreKnow Your Borrowing Options

Growing shops need two lenders to maintain profit margin: a bank and an equipment leasing company.

Read MoreLaser Texturing Proves Automotive Potential

A cosmetic interior tooling application in North America could spell a brighter future for a process that promises savings throughout the supply chain.

Read More