MMT Blog

Let the Good Times Roll

Data from SPI shows that shipments of plastics machinery rose significantly in the fourth quarter of last year. Let’s hope this trend continues.

Read MoreThe Designer's Edge: Plastic Part Sticking, Part 1

Most of you have experienced issues with a plastic part sticking in the cavity, core, lifters, slides or ejector pins, and a typical response is to polish or add undercuts. However, if you understand how materials react to certain surface finishes and temperatures a more robust solution is possible. Opposite side showing the ejector pins.

Read MorePlastics Saving Lives (Includes Video)

Our industry impacts people in ways that might not be obvious from the day-to-day experience of working at a mold shop or molding operation. We recently covered one example, and organizers of NPE will showcase another.

Read MoreCome Out and Support Education

AMBA Chicago Chapter is hosting a Supplier Night Fundraiser on April 22 to support its Education Committee's continuing efforts to promote moldmaking as a viable career.

Read MoreA Comprehensive Plastics Education at NPE

Given all the services and capabilities expected of modern toolmakers, “mold manufacturer” is practically a misnomer these days. Whatever the topic, we’ve likely got you covered at NPE with an extensive lineup of presentations on all things plastic.

Read MoreDream it. Code it. Win it.

With our recent efforts to promote career opportunities in mold manufacturing with our MoldMaking Matters: Your Career Can Make a Difference video, I thought I'd share this post about the second annual award-winning "Dream it. Code it. Win it." contest, which is a student coding competition that rewards and promotes creativity, diversity and literacy in the field of computer science.

Read MoreWide Open Opportunities

The future is looking bright for the subject of this month’s profile article, which has plenty of room for expansion.

Read MorePower to Change

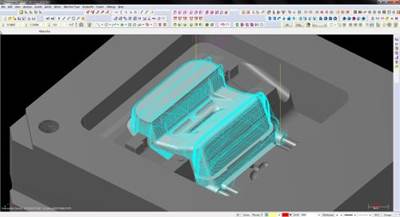

Paragon D&E's ‘Power to Change’ motto entails its team working together to create methods for doing things more efficiently and trusting their decisions. A key component to that philosophy is its powerful CAD/CAM software.

Read MoreAdditive Recycling Program Supports a Cause

Additive manufacturing system supplier Stratasys’ new recycling program will impact more than just customers’ bottom lines. It’ll also contribute to a cleaner environment and job opportunities for the disabled.

Read MoreThe Designer’s Edge: Impacting Flash

Randy examines how the moldmaker can impact flash with a look at parting lines in the design. Whenever you have flash you need to understand the root cause. For example, is it wear from low draft angle shut-offs, poor shut-off conditions, thermo-expansion, or erosion or damage from a crushed part or runner? If you understand root cause, you can focus on future prevention.

Read MoreRefusing to Settle

This toolmaker’s efforts with design software and aluminum production tooling reveals a drive to challenge conventional practices and push capabilities to the limit.

Read MoreA Flexible Strategy for a Flexible Shop

“Dynamic” is a fitting term for both this mold manufacturer and a CAM software capability that helps adapt to widely varying cutting conditions.

Read More