MMT Blog

Making a Change

I have been serving as secretary for the SPE Mold Making and Mold Design Division for the past couple of years, and one important item on our to-do list has been to change the Division name to one that is more fitting of our updated mission statement. We can now check that off of the list.

Read MoreAnother Look at a Compelling Succession Story

An article in a sister publication offers a nice complement to MMT’s own coverage of the Bales sisters, who took over their company under tragic circumstances.

Read MoreRedefining CAM Technology for Moldmakers

Tool paths that dynamically adjust tool motion allow faster, safer machining without the need for high-speed equipment.

WatchReusing CAD Data

A true direct modeler can help mold builders work more easily with customer design data.

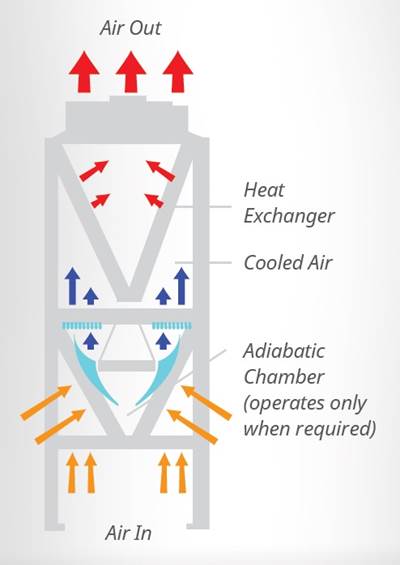

Read MoreLet's Talk Water Conservation

In a recent survey, water conservation was ranked a top concern by nearly two-thirds of respondents and 30 percent said that process cooling accounts for more than half of their plant's overall water usage.

Read MoreThe Breadth of Conformal Cooling

Conformal cooling provides faster and more uniform dynamic heat transfer within in injection molds.

Read MoreControlling Your Hot Runner Manifold System

Moldmakers and molders need to better understand modern hot runner controller technology to solve processing problems.

Read MoreCryogenic Basics

Cryogenic machining technology milling fluid end component made of 4340 high alloy hardened steel.

Read MoreCAM Automation is a Process, not a Goal

Automated NC programming requires a strategy to yield improved productivity, quality and consistency.

Read MoreElectronics and Automotive

Electronics could see stronger growth, while automotive production likely to slow in 2016.

Read MoreIncrease Your Shop’s Financial Viability

Comparing machine tool performance against clearly defined metrics can help you maximize utilization and therefore improve shop operations.

Read MoreCryogenic Machining Eliminates Moldmaking Conundrum

As moldmaking material gets harder and more expensive to cut, suppliers are “caught between a rock and hard metal,” balancing production costs with customer needs. Cryogenic machining with through-tool liquid nitrogen makes production of longer-lasting molds efficient and affordable.

Read More