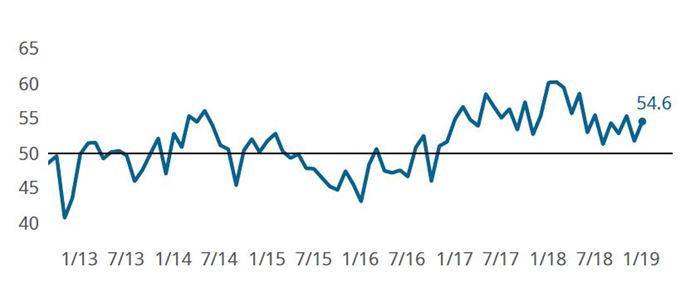

Moldmaking Index Starts off 2019 Advancing on Production, New Orders

January 2019 – 54.6

Share

The Gardner Business Index (GBI): Moldmaking started off 2019 by moving higher to 54.6 thanks in part to the accelerating growth trend in both production and new orders since the second quarter of 2018. Compared to the same month one year ago, the index has fallen 9.8 percent; however, data from January and February of 2018 represent both the peak growth rate of the current economic cycle, as well as all-time high readings for the Moldmaking Index. Compared to the average expansionary reading for the Moldmaking Index since 2017 — representing the start of the latest growth phase for the industry — January’s reading was within 1-point. Gardner Intelligence’s review of the underlying data for the month reveals that production, new orders and supplier deliveries lifted the index — a calculated average of the components — higher. In contrast, employment, exports and backlogs pulled the Index lower. Excluding backlogs, all components reported an expansionary start to the new year.

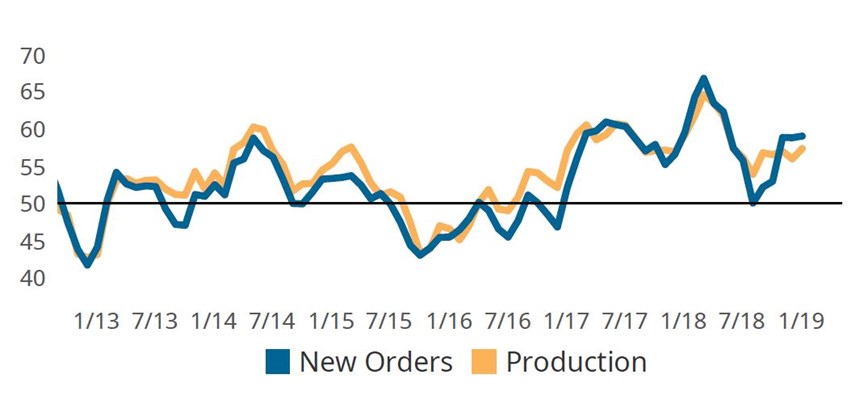

Gardner Intelligence was encouraged by January’s strong production and new orders results, as these components are often considered leading indicators among the other components. Rebounding strength in new orders during the fourth quarter of 2018 and the first month of 2019 after a brief slowdown in the third quarter will likely bolster readings for production, supplier deliveries and backlogs in the near future. The outlook of employment and export expectations in 2019 are more tenuous as they will be subjected to unique factors, including an exceptionally strong job market, which has resulted in many manufacturing positions going unfilled and the success of future trade negotiations respectively.

For More Information

Stay ahead of the curve with Gardner Intelligence.

About the Author

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

Moldmaking Activity Begins 2024 With Slowed Contraction

January index reading reflects February-March 2023 readings as it slinks toward a reading of 50. There are high hopes that it may continue on this path to sustained expansion for 2024.

-

Moldmaking GBI Returns to Contraction After One-Month Respite

After a challenging move into the 50s in March, the April GBI returned to a mostly consistent state of contraction, the result of recent market dynamics.

-

Moldmaking Activity Contraction Slows in August

Future business expectations still improving, but more slowly.

.jpg;width=70;height=70;mode=crop)