MMT Blog

How to Take Advantage of AI for Machine Monitoring

Artificial intelligence (AI) can help shops reduce preventative maintenance costs and increase production and efficiency gains.

Read More2020-2023 Editorial Advisory Board: Meet New Board Member Don Smith

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

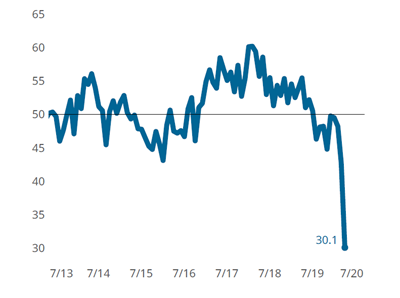

Read MoreMoldmaking Index Registers April Collapse in Business Activity

Survey respondents report collapse in new orders, driving the Moldmaking Index down 13 points for April 2020.

Read MorePrecise Tooling Solutions Deploys First U.S. Viral Sign Installation

Viral Sign, Inc. announces the launch of the company's advanced screening technology at the manufacturing facility for Precise Tooling Solutions in Columbus, Indiana.

Read MoreMold Builders Turn Challenge into Change Amid the Coronavirus

As soon as coronavirus hit the states, I connected with shops across North America to gauge the mood and current impact on business levels. What struck me was not the insight they provided each time I checked in, but their readiness and willingness to help and their consistent look on the brighter side.

WatchPODCAST: Exposing the Secrets to Success

Three American Mold Builders Association executive board members talk about the advantages of building relationships and sharing what you know.

ListenBack to Work Planning Underway for Canadian Manufacturing

Return to work guidelines are on the radar and underway for Canadian manufacturing, and it’s clear that manufacturing is focused on the next 90 days and that repairing for new health and safety standards in the workplace is important.

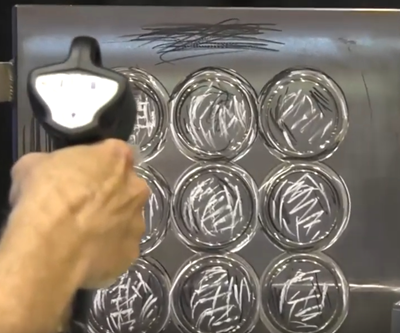

Read MoreDry Ice Provides Optimum Range of Possibilities in Parts Cleaning Process

Cold Jet LLC showcases how they use dry ice (solid CO2) in their parts cleaning process.

WatchMMT Chats: Fighting COVID-19 with Collaboration

Next Chapter Manufacturing, Muskegon Community College, PCS Company and Concept Molds chat about a coalition they formed to produce face shields to help fight COVID-19.

WatchA Virtual Handshake Takes on COVID-19

After being deemed an essential business, this worldwide Tier 1.5 supplier to the automotive industry used its best judgment, put the right protocols in place to keep employees safe within its 50,000-square-feet facility, and got to work on making face shield molds—all as a result of a virtual handshake.

Read MoreHow to Improve Mold Machining with the Right Control Functions

Fine tune machine setup, minimize forces and deviations, improve accuracy, and manage automation with proper control.

Read MorePODCAST: Tackling Problems with Relationships and Processes

Currier Plastics’ Ron Ringleben, vice president of business development, and Sriraj Patel, director of research and development, discuss how their company builds relationships and tackles problems for their customers in this episode of The Manufacturing Alliance podcast.

Listen