While buzzwords such as predictive maintenance, artificial intelligence, digital twin and augmented reality have promised to enable the fabled digital transformation of manufacturing, when it comes to Industry 4.0, most practical applications start and end with machine connectivity. And when it comes to driving value, look no further than answering these questions: “What’s happening?” and “Why is it happening?”

Most manufacturers are unable to see what’s happening on the shop floor in real-time because their machines are not connected to any data collection or data visualization system. This inability to see and use data to drive continuous improvement leads to massive inefficiencies that affect every component of a company’s operations, from the shop floor to the C-Suite.

Here is a look at where artificial intelligence (AI) lands within the analytics journey and its relationship to technologies such as machine monitoring and data collection.

Making the Move to Machine Monitoring

Manufacturing industry is progressing with taking advantage of AI for machine monitoring, but manufacturers are tackling some difficult challenges. As a whole, manufacturing struggles with modernizing effectively in the face of antiquated and ingrained cultural traditions. Often the metric in manufacturing is the tangible end product, so as long as the end product looks good and sells, we sometimes don’t want to bother with the rest of the process. This makes it hard to drive change and modernization.

For machine monitoring specifically, it gets even harder. Manufacturers can be hesitant to have their data leave the shop, so most machine monitoring companies do an on-premise implementation. This approach leads to siloed data, which makes it tough to aggregate enough data and across sufficiently diverse domains to train an AI model. Imagine if Netflix tried to build a recommendation engine but only had data from one household.

During the last few years, there have been one-off, single-purpose models that aren’t very helpful outside their respective domain or company. Another option is a pure-cloud solution (not an on-premise solution) that pulls together a representative sample of manufacturing processes across the discrete manufacturing space. This approach helped developed more general-purpose AI algorithms for detecting failure on multiple different types of processes and machines.

Even after tackling the issue of siloed data, there remain many outstanding issues, both technical and cultural. For example, data can be very messy and inadequately labeled; employees may resist any implementation of AI in the shop, seeing it as an affront to their job security; and there can be a general lack of understanding of AI’s current capabilities and limitations. Manufacturing is slowly working through these problems, so AI adoption will only become greater.

The ultimate goal of AI for machine monitoring is not to replace humans, but to supplement their expertise with additional, computer-guided capabilities to make the shop run smoother.

Taking Advantage of Artificial Intelligence

Assessing the Options

Today, there are several forms of machine monitoring used in manufacturing environments beyond sensors on machines. The two general types are the low-cost/free types that are specifically for small manufacturers, and the huge, enterprise-level applications that need to be customized for different manufacturers, like the ones sold by giants like IBM.

On the low-cost end, these can be quick to implement but have extremely limited capabilities, such as only displaying when a machine is up or not and what percentage of the time the machine has been used. They can also be buggy and unmaintained. Generally, they’re known as lightweight solutions that solve one very specific problem, such as tracking parts or monitoring uptime, but not both.

On the higher-cost, enterprise end, these require long implementation timelines and a huge upfront cost. Today, there are plug-and-play vertically integrated IoT platforms that are also feature-rich and extensible to create continuous value and innovation.

Computer vision is another area that’s maturing in manufacturing. Installing cameras inside the machine and around the shop floor is helping manufacturers automatically identify product defects, track inventory and generally make the shop a more automated experience. Again, this is in its infant stages, so impact is limited, but as time goes on, this type of technology will only get better.

Monitoring the Future

The ultimate goal of AI for machine monitoring is not to replace humans, but to supplement their expertise with additional, computer-guided capabilities to make the shop run smoother. We find that shop culture gets better with more visibility. Employees can reference data when driving decisions, and transparency helps foster an environment that’s healthier in the long run.

As to replacing jobs, when a piece of software is able to automatically track the number of parts created and how often the machine is up or down, workers’ time is freed up to do higher-value tasks, like running initiatives to improve efficiency across the shop floor with data collected by the computer program. The higher revenue that the company realizes can be reinvested into worker-training programs, so that workers doing rote tasks can be retrained for positions focused on management and strategy.

I predict that AI will be able to help manufacturers drive down costs through preventative maintenance and increase revenue through increased production and efficiency gains. However, I warn readers about the danger of yielding decisions purely to AI without human context. Smart managers will always seek to understand why the AI recommendation occurred and supplement it with human input. Just like with relying on AI for anything, like self-driving cars, you need to still stay awake or you’re going to crash and burn.

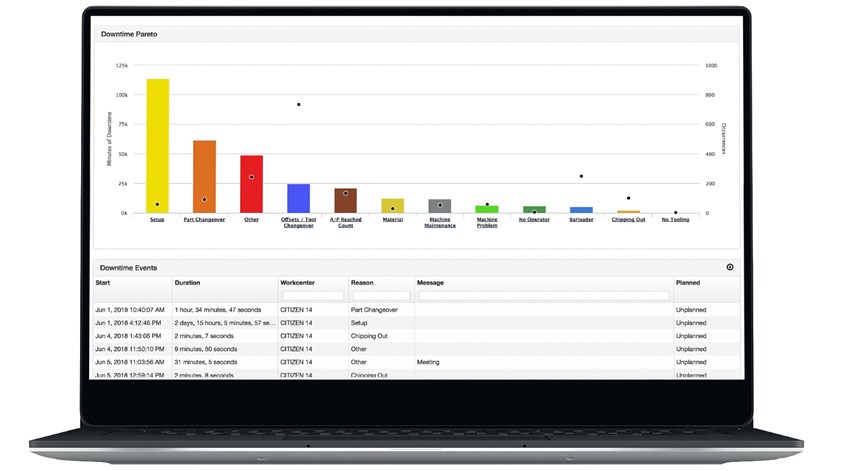

My final advice for the manufacturer who wants to start incorporating AI-based machine monitoring is to start with the basics. Walk before you run. If you have no digitization or automated visibility into your processes, start with descriptive analytics. Just knowing when your machines are or are not running can help to uncover obvious things about the business. For example, discovering that machines are sitting idle for two hours at the beginning of the first shift. Something like this can help save thousands of dollars right off the bat without any fancy machine learning algorithms.

As to costs and considerations, it’s important to get buy-in from not just one party, but multiple key stakeholders in the business before embarking on a machine-monitoring project, even without AI. It’s a complicated venture into new, pioneering territory for most shops and can easily fail without organizational maturity and a steadfast eagerness to see change and improve.

Evaluating if your company is the right fit for machine monitoring and advanced analytics is important. Managers should be considering what types of efficiencies they’re looking to drive and realize it’s not a magic box that will solve all their problems without some effort. The journey into AI and machine monitoring is a partnership that requires constant learning and a thirst for knowledge on all sides.

Related Content

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreTake Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreRead Next

Tooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)