Back to Work Planning Underway for Canadian Manufacturing

Return to work guidelines are on the radar and underway for Canadian manufacturing, and it’s clear that manufacturing is focused on the next 90 days and that repairing for new health and safety standards in the workplace is important.

Return to work guidelines are on the radar and underway for Canadian manufacturing — ahead of the announcement by the Province of Ontario Thursday.

It’s clear that manufacturing is focused on the next 90 days and that repairing for new health and safety standards in the workplace is important. The main concern for employers is that 43% of workplaces report not having sufficient personal protective equipment (PPE) specific to the prevention of virus spread. Work is underway to identify the exact nature of the shortages and to develop supply chains to find PPE.

With a ramp up rapidly approaching and workplace safety practices and requirements changing daily, planning for this is underway.

The weekly surveys by the Canadian Association of Mold Makers’ (CAMM) and Automate Canada’s have painted a picture of a manufacturing sector in Ontario that was initially hit hard by COVID-19 and is now focused on planning for resumption of operations at production facilities.

The Canadian Emergency Wage Subsidy (CEWS) program tops the list of programs being accessed by manufactures, based on this week’s results. The data shows that temporary layoffs have slowed significantly, while “furloughs” have increased, effectively retaining employees with government assistance. Knowing that the mold, tool, die and industrial automation industries are looking near term to supporting the ramp up of major manufacturers, employee retention is critically important.

“Clearly some workplaces are getting ready and in search of PPE. We are looking to see how we can assist and connect them as requested to sources for these items,” says CAMM Board Chair Mike Bilton. “These surveys are helping not only us in our advocacy work but also making a difference for our members and this industry.”

Shelley Fellows, chair of Automate Canada, says data does rule in terms of getting the attention of government and even others in the industry. “We are starting to see trends and we can also work to provide help where we see needs.”

Financial concerns continue to weigh heavily on respondents, which represent primarily the mold, tool and die industry as well as industrial automation sector. CAMM and Automate Canada have been assisted in the distribution of each week’ survey by the Canadian Tooling & Machining Association (CTMA).

On Tuesday, April 28, CAMM and Automate Canada hosted an “Ask Us Anything” webinar to deliver detailed information on financial programs for manufacturers from the government as well as banking, with an expert panel comprised of Business Development Bank of Canada, Export Development Canada, Royal Bank of Canada, KPMG Canada and the Ontario Ministry of Economic Development, Job Creation & Trade.

CAMM and Automate Canada have also launched a bi-weekly “deep dive” study into the cash flow concerns expressed in the surveys. Results for the first financial study will be released soon.

Responses this week were primarily from the Southwestern Ontario region, which has a significant manufacturing, moldmaking and industrial automation cluster. Key points include the number of employees out of the workplace due to isolation or quarantine is up this week, up to 73 in total compared to 58 the previous week. The number of employees laid off decreased this week, declining to a total of 90 employees laid off temporarily, compared to 143 in week five. In the past seven days, there were a total of 515 “furloughed” employees, up from the 395 reported as furloughed the previous week. This week, respondents reported hiring eight new employees. Requests for quote are up at a level higher than temporary delays and almost equal to cancellations, which is good news. Almost half of respondents predicted they will be at over 90% of full operations by the end of this week. 43% of respondents said they do not have sufficient PPE in their workplaces. It looks like only a handful of companies are getting calls for clarification from Service Canada and none of the applications will be declined.

A COVID-19 Impact survey from CAMM and Automate Canada will go out weekly based on the feedback we are receiving. The questionnaire for the financial study was released on April 16.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

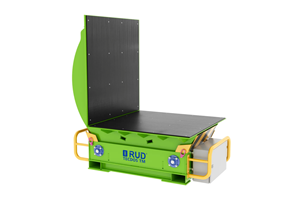

Read MoreIndustrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreMMT Chats: Resilience Through Relationships After a Hurricane

A mold builder’s story of resilience, teamwork and growth after Hurricane Helene devastated their community.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More