MMT Blog

Just a Few Words on Why and How We Work Through COVID-19

This mold component supplier shares its reasons for continuing to work and steps for ensuring your business remains open and operating at normal levels.

Read MorePopular Posts: April 2020

These popular blog posts from April 2020 feature a topic that has been on everyone’s mind in the past month: coronavirus and how the moldmaking industry is adapting to this global crisis.

Read MoreBeing Connected to Community and Customers during COVID-19

Mold manufacturers and technology suppliers across North America have day jobs and night jobs when it comes to doing more to help both their customers and local communities during the coronavirus pandemic. Here is one mold component supplier’s story.

Read MoreThree Generations of Moldmakers Support Injection Molding and Investment Casting Industries

It’s all about service: a family mold, tool & die shop goes above and beyond for plastic injection and investment cast customers.

Read MoreTooling Innovation Provides Relief to Mask Shortages

2K Tool in Grand Rapids, Michigan, is helping to protect citizens with its quick turnaround on face mask tooling.

Read MoreMMT Chats: COVID, Communication and Customers with CDM Tool & Mfg

CDM Tool & Manufacturing expedited and maximized resources with supplier support to be part of a solution in the fight against the coronavirus.

WatchPODCAST: Always In Pursuit of Teamwork

This speed junkie is determined to use teamwork to make better decisions, and it’s working. Tony May is the vice president of business development for engineering-driven mold builder Pyramid Mold & Tool located in Rancho Cucamonga, California which focuses on complex, multicavity tools.

ListenCOVID-19 Gives Mold Component Supplier Its Most Consequential Order Ever

The pandemic has presented challenges to every link in the mold manufacturing supply chain and those companies in a position to help have put their teams and processes to the test, including mold component suppliers.

Read MoreRush-Produced Core Pin Tooling Proves Critical for COVID-19 Test Kit Production

I can't help but share another news release that came across my desk, as it again showcases the essential role of mold component suppliers in the development of tooling to make products and equipment to fight the coronavirus in record times.

Read MoreMold Builder Just Figures It Out: From Face Shield Mold Design to Sales on a Site in 6 Days!

Within three days, Bryne Tool + Design of Rockford, Michigan, sold 4,000 face shields at $2.95 each (and available in 10 packs) from a mold that ownership donated.

Read MoreCommunity Addresses Coronavirus PPE Backlog with 3D Printing

As the COVID-19 crisis has deepened, Rocklin Manufacturing has been addressing the need to fulfill the growing PPE backlog by not only turning to 3D printing, but by also connecting with its local community.

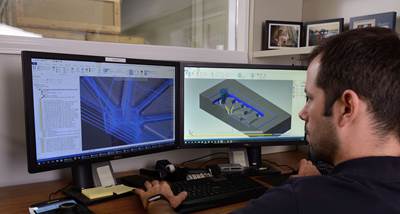

Read MoreCAM/Cutting Tool Combo Improves Mold Finishes

Combining CAM software, specialty carbide end mills, and reseller support optimizes existing mills for machining molds at an electrical components manufacturer.

Read More