MMT Blog

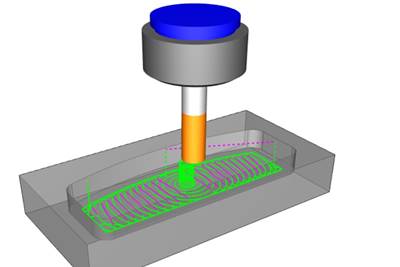

Amerimold Connects Kicks off with Tool Shop Live Demo of a High-Level Hot Runner Mold PM

The reason we are kicking off the event with this topic is because at the heart of making things is the mold, and since the mold impacts every link in the supply chain—OEM/brand owner toolrooms, molding facilities and mold building shops—mold maintenance is vital. So we felt it’s only appropriate to kick off this event with a “virtual” hands-on look at a proper hot runner preventative maintenance routine.

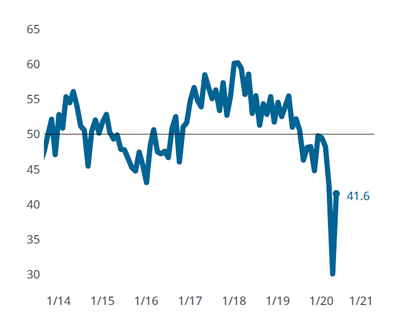

Read MoreMoldmaking Index Advances as Components Move Towards ‘Normal’ Levels

The Moldmaking Index signals decelerating contraction as all components report improved readings.

Read MoreMMT Chat: Safety, Shields and Shuttle Molds

The team from Canon Virginia talks about business during COVID-19, its efforts to help the fight and recent advancements to its Shuttle Mold System.

WatchPODCAST: Meeting Up in Mexico and Talking Shop

Meximold 2019 was an opportunity to sit down with the editor of the event’s publication Plastics Technology Mexico and with the project manager of a Canadian mold builder that opened up a facility in Mexico to capitalize on its moldmaking opportunities.

ListenVIDEO: MMT Goes Onsite (Remotely) to Spotlight Precise Tooling Solutions

COVID-19 may have prevented the MMT team from visiting our 2020 Leadtime Leader winner in person, but we still sat down with the team “virtually” to help share their story.

WatchVIDEO: 2020 Leadtime Leader Award Winner: Precise Tooling Solutions Inc. — The Power of People and a Plan

The proof is in this winning shop’s three-pillared value proposition and three-phase growth plan that promotes empowers people while promoting quality product and profit.

WatchSnapshot of Why Precise Tooling Solutions is MMT's 2020 Leadtime Leader Winner

Here is a quick look at some of the reasons this small specialty manufacturer took the title this year.

Read MoreVIDEO: Official Announcement of MoldMaking Technology's 2020 Leadtime Leader Award Winner!

Each year, the moldmaking industry recognizes excellence in mold manufacturing with MoldMaking Technology’s, Leadtime Leader Award. It’s not just about being the shop with the shortest delivery times. It’s about what you do with what you have. Meet this year’s winning shop!

Watch8 Mold Design Decisions That Impact Automation

Making the right decisions during eight key mold design phases will avoid automation problems and save money on price, installation and operation.

Read More5 Ways to Cut Programming Time

Steps mold builders can take to reduce programming times and improve machining processes.

Read MoreMMT Chats: COVID-19 Highlights Value of Diversification

I sat down with a trio from Decatur Mold Tool & Engineering in North Vernon, Indiana, for a quick chat about their recent COVID-related project and a couple of lessons the team learned.

Read More