A Virtual Handshake Takes on COVID-19

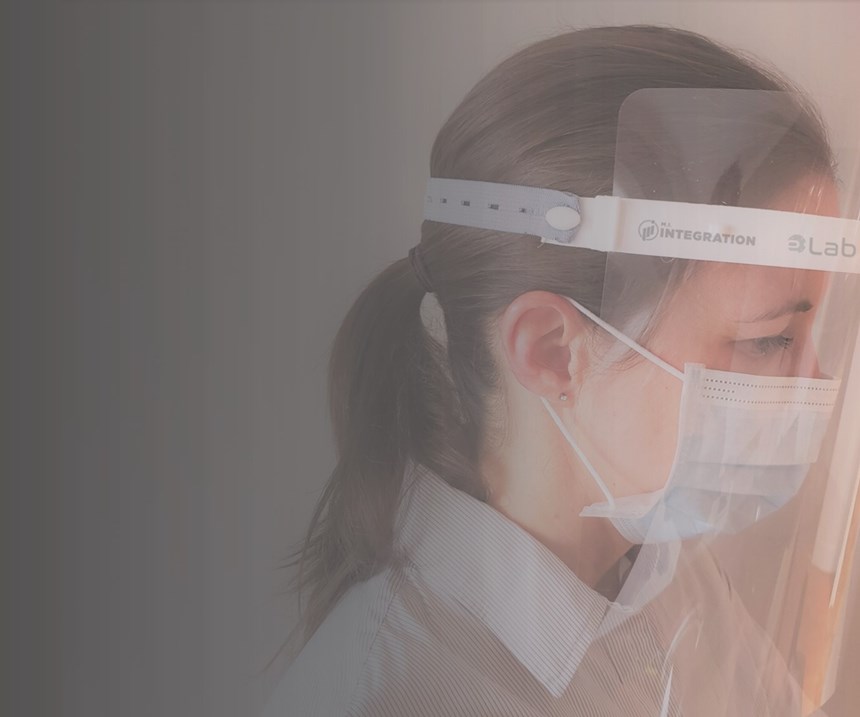

After being deemed an essential business, this worldwide Tier 1.5 supplier to the automotive industry used its best judgment, put the right protocols in place to keep employees safe within its 50,000-square-feet facility, and got to work on making face shield molds—all as a result of a virtual handshake.

Face Shields and a Former Employee

M.I. Integration does mold building and molding work for some critical automotive and defense industry projects. Still, as the virus hit, the injection molding facility was shut down, temporarily laying off all the employees. With its top priorities being the health and safety of its people and the financial health of the company, M.I. management focused on managing its cash flow properly and connecting to all available government aid to minimize the impact on its workforce.

“Once things settle down, we will need to adjust to a 25-30% drop in business throughout the next year, so we are preparing now. We are thinking about how to put our structure back in place to make sure that we will still be profitable, Vincent Houle, President at MI Integration, says.

Then a former employee who left M.I. Integration to start his own business, eLab—an engineering services provider—reached out to Houle about some open-source data to make face shields and asked if M.I. would be interested in 3D printing and injection molding some parts and tools.

“I saw the wave coming, so I decided to take on this project, entering the medical space. We put our teams together to create a new face shield,” Houle says.

Partnering Up

This partnership involved no paperwork and no lawyers; only the teams meeting and building trust. “What I'm learning is there is too much bureaucracy in ordinary times to progress quickly. We both just wanted to get products on the market for the frontline workers,” Houle says.

They started with daily meetings to see what could be done differently instead of just taking the open-source data and making what was already in the field. They were on a mission to improve the design.

“We 3D printed different versions—we are on version 14—and we now have a re-usable concept where users will be able to clean the shields. All other face shields that exist on the market right now have foam integrated to face shield making it disposable,” Houle says. At first, they didn't know that it would be a good feature of the product, but it was, in fact, their differentiator, and they started getting a lot of interest.

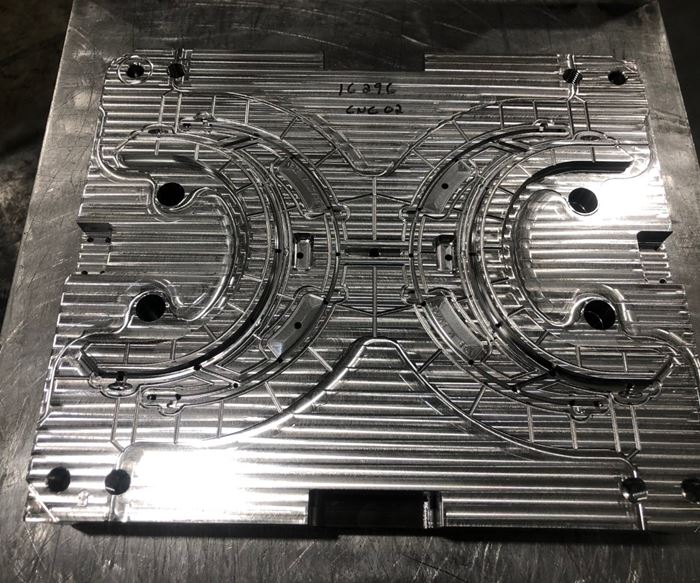

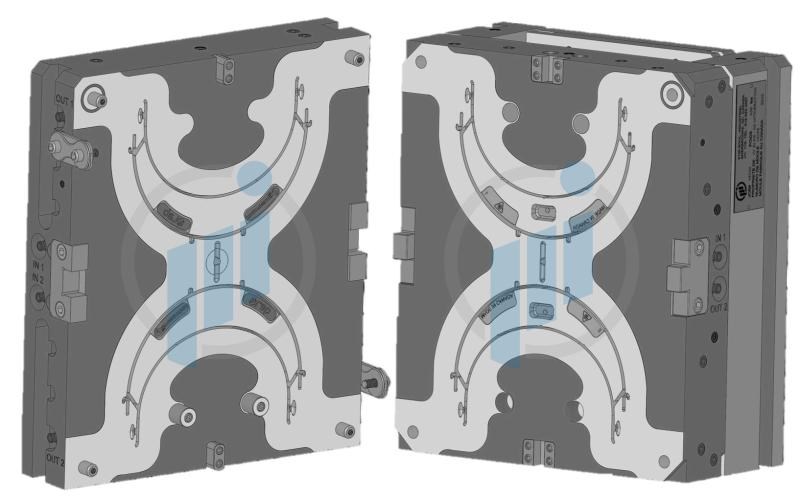

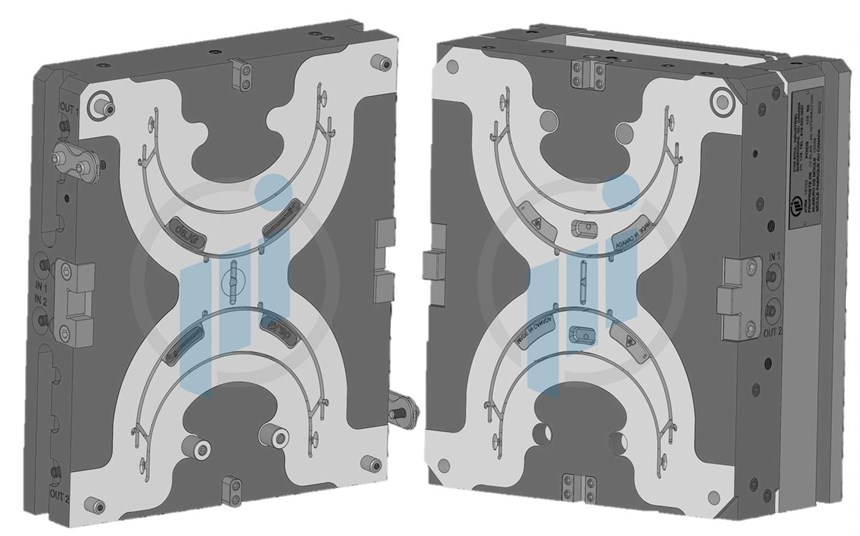

The urgency to get these face shields on the market to frontline workers motivated the team to kick off the two-cavity production mold and complete it in less than two weeks. They put all of the company’s resources on this job. It is a simple design. Plus, they designed the mold using everything they had in inventory, so they didn't have to contact any supplier, which would have increased the lead time.

“It’s not a typical lead time or a typical product, but the work was vital to the safety of our frontline workers,” Houle says.

M.I. was able to generate 25,000 face shields a week when a distributor—connected to the government—reached out to Houle asking if they could handle producing 6 to 10 million face shields. Well, this opened up M.I.‘s injection molding facility. They analyzed the mold, looked at their range of presses, and started considering different mold configurations.

“I could build an eight-cavity mold, two four-cavity molds, and one two-cavity mold to increase our capacity to 400,000 to 500,000 face shields per week. I communicated that to the government, and we are awaiting an answer,” Houle says.

All of this work has allowed M.I. to recall laid-off workers on both the moldmaking and molding sides of the business. They are planning to start full production and adding a third shift to work with the two-cavity mold right now.

When asked what he’s learned so far into this crisis, Houle says, “It's more than just a postmortem on how we built the mold so fast; it’s also about the process of getting a product to market fast.”

The key to doing that for these face shields was relationships and trust. Houle prefers to have an agreement with a handshake–today, a virtual handshake—as opposed to a lot of paperwork slowing down product development and manufacturing. “Trust is what lead me to take on this face shield project and diversify into medical work. It’s hard to build relationships in automotive. It’s all about coming together as people just to get the project done and get the product on the market.”

Houle says the company usually has a 3- to 5-year strategic plan built upon business intelligence and trend analysis but this coronavirus put M.I. in a situation where they needed to adapt very quickly to a very fluid situation.

“It has changed the way that we manage the business. It has made us more proactive and quick to react. We shouldn't wait. Instead, focus on the current opportunities in the market like we are with the medical work. Next on our list are reusable N95 masks and hospital beds. We want to keep our talent occupied with projects,” Houle says.

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)