Simulation Success!

Real-world applications of simulation software reveal tips for how to achieve faster iteration of more ideas, giving engineers more ways to address common problems such as warpage.

Molds are expensive, so it confounds me that many shops still do not employ technologies and strategies to predict where something may go wrong before they start making chips. Don’t you want to know what could go wrong upfront, so you can prevent it from happening instead of modifying a tool?

This is what many experts in the field of plastics analysis have been promoting for more than 30 years—all in an effort to help companies make better part and mold design and injection molding decisions.

The answer is simulation.

Eliminate Warpage

Some common areas of interest among MoldMaking Technology’s readers include core deflection analysis, material characterization, sizing overflow wells, final coring, predicting good layouts, conformal cooling analysis, high shrinkage and voids, optimizing fill time, pressure, clamp force, shot size, packing, runners and gates, shear stress, shear rate, residual stress, venting, identifying alternative molding processes, valve gate sequencing, etc.

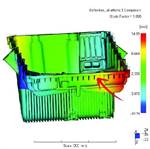

But here I want to highlight warpage. More specifically predicting and preventing warpage. I want to recommend a new ebook from Autodesk that provides a practical approach to reducing warpage in injection molded parts using three case studies involving simulation based on actual customer experiences.

Some quick tips include:

- Warpage optimization should be performed last after other steps have been perfected Because it depends so heavily on many other factors. Optimizing warpage essentially encompasses the outcomes of all the preceding steps, and so the decisions made during these steps will influence the results of the warpage analysis.

- Up-front analysis of warpage does not have to be done with extreme precision if the intent is to gain initial guidance rather than drive more rigorous optimization.

- When you generate results from the first warpage optimization analysis, you must determine the magnitude of warpage and identify why the part is deflecting.

- Two typical causes of warpage are non-uniform cooling and inconsistent shrinkage.

- A DOE is a key statistical tool that enables mold engineers to see how changing a processing variable affects the quality of the part. DOE analyses search for optimal processing conditions by automatically running a series of analyses while varying the values for selected processing conditions.

- Parametric optimization allows teams to evaluate multiple gate locations to identify the best solution.

- There is no one “correct” approach to minimizing warpage. To find the right approach for your project, you need to first detect the potential for warpage through accurate simulation and identify the cause. Only with this knowledge can you determine how best to minimize warpage.

Related Content

-

How a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.