Quality Control Technologies Geared for Injection Molds

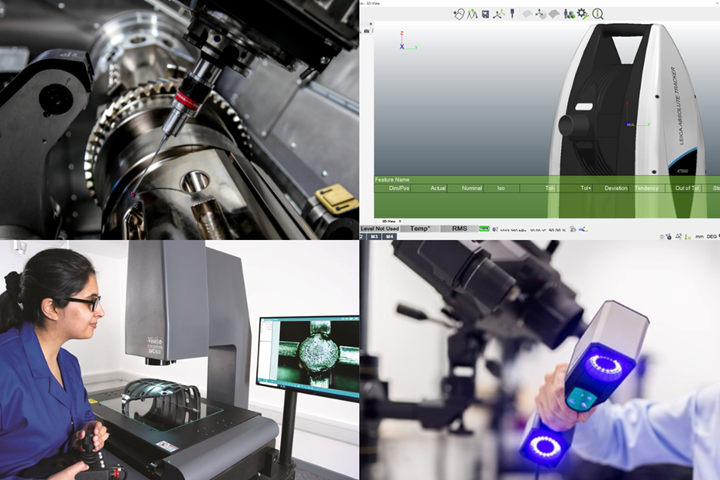

These latest technology solutions, from noncontact gages to test probes and automated inspection systems, aim to minimize production risks and ensure optimal quality control practices for moldmaking.

Quality control and quality assurance practices are critical for developing injection molds that meet all fit and function requirements, as well as ensuring the production of precise plastic parts. Measurement technologies are capable of thoroughly inspecting and testing these molds to identify and rectify any deviations or defects in a timely manner. They span from noncontact gages to test probes and automated inspection systems, some of which are detailed in this latest technology roundup. A more comprehensive list of solutions can be viewed here.

Linear Height Gage for Mold Measurements is Highly Digital

The Mitutoyo America Corp. LH600F/FG linear height measurement system, suitable for moldmaking, is the latest model in the Mitutoyo Linear Height Gage line with several added features and benefits. It features a high-accuracy scale unit and high-accuracy guiding mechanism manufactured in-house.

Touch Probe Delivers Fast, Precise and Reliable Mold Inspection

Blum-Novotest, a manufacturer of innovative, high-quality measuring and testing technologies, features its Digilog test probe systems that enable high scanning and probing speeds in the hard-use, high-output molding environments. Complex contours can be monitored in series at up to 2 m/min to increase productivity while maintaining strict specifications.

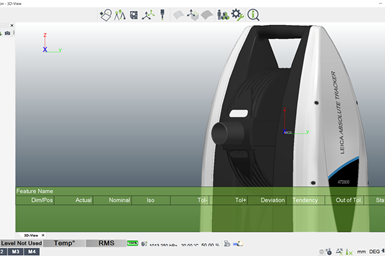

Universal Metrology Software Connects All Measurement Devices to One System

NextMeasure, a startup measurement software company that puts the user experience first, highlights how its universal metrology software enables highly efficient measurement systems so that moldmakers are able to inspect and measure any and all molds in any location, at an affordable price point.

The offered software is different from other traditional metrology options, NextMeasure notes, which are often tied to specific brands.

Automated Three-Axis Achieves Accurate, Repeatable Quality Control Results

Vision Engineering Inc. boasts decades of experience in supplying accurate, measurement and inspection systems, whether to measure critical plastic part features, or check mold tools and extrusion dies for signs of wear and damage. In particular, the company’s LVC Series of automated three-axis measurement systems is ideal for injection molding and manufacturing companies looking to improve the speed and efficiency of part inspection routines.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

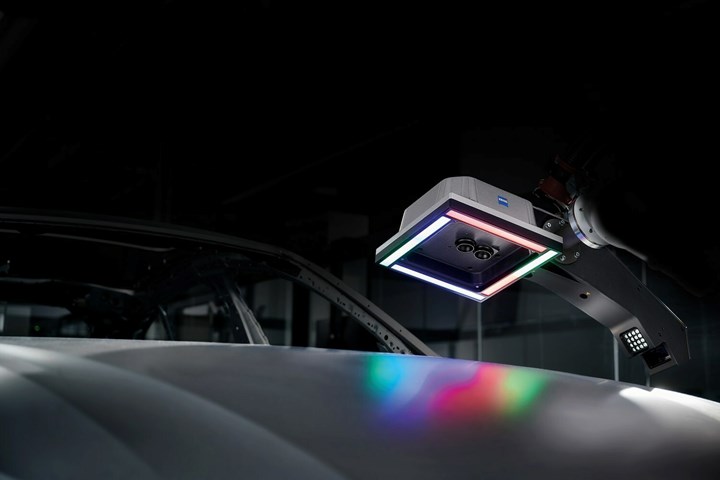

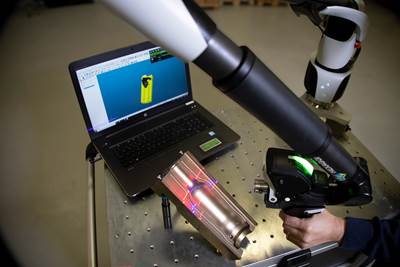

Three 3D Scanner Investment Considerations

Mold builders taking advantage of laser and software advancements for portable 3D measurement tools can reduce inspection and measurement times.

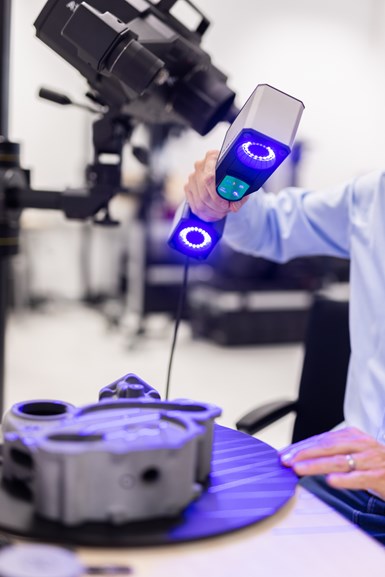

Read MoreIntuitive, Easy-to-Use Inspection Software for Portable Probing and Scanning Simplifies Mold Measurement

Enhanced inspection software and hardware with portable measurement, analysis and reporting improves productivity.

Read MoreTechnology and Sourcing Guide 2023: Inspection/Measurement

Inspection and measurement equipment includes all of the tools and devices used to verify that mold and part dimensions conform to the tolerances required by the part’s design

Read More