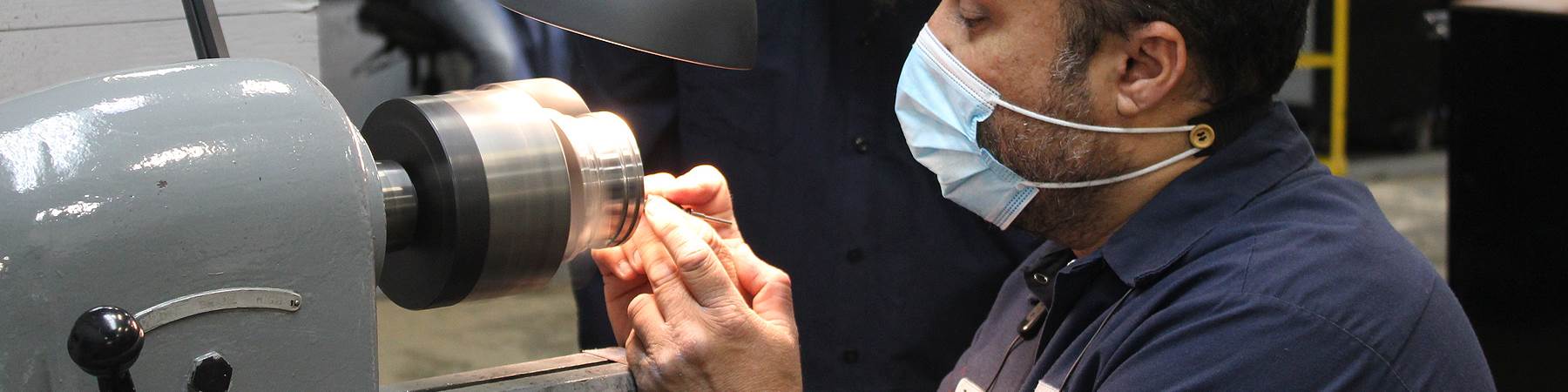

Experienced polishers share best practices every day with polishing apprentices to provide the optimal results for demanding customers. Photo Credit: Alliance Specialties and Laser Sales

Many mold manufacturers build a network of specialty shops to whom they outsource steps of a project to help meet required deadlines and stay on budget. These relationships demand communication at every step to ensure a quality mold on schedule. This means that before a job hits the floor of that specialty service provider, the mold builder and service shop managers must communicate expectations and requirements.

For example, preventative maintenance (PM) is essential when it comes to improving mold performance, so working with your maintenance provider to schedule downtime will save time and money in the long run. When scheduling maintenance, the mold builder must be open and honest about their availability, so the maintenance provider can prioritize the job before it even arrives at the shop.

The same goes for mold finishing services, although with this process comes a bit of subjectivity which must be discussed upfront to alleviate miscommunication. For example, an A2 finish can mean very different things to different people. Plus, polishing is an art and not a step to rush. Providing as much time as possible to adequately prepare and ensure a service provider has open team members to work on a hot job is critical.

Skilled TIG and laser welding specialists are continually trained on the latest technology and processes.

Laser welding and laser engraving services also require ample attention to detail and optimal foresight to determine which process or combination of processes to use. For example, understanding when to prep a weld before doing a chrome buildup, and understanding the depth of the engraving itself, not the depth of the plastic.

These services may encounter unexpected issues, which may require added cost for the mold builder, so prompt communication is key. It is never wise to send an updated bill with added labor and additional costs. Instead, include a paper trail of the details with every job—photos, emails, phone calls, last shots, marked-up parts and contact information. These simple steps provide accountability for both parties.

Here are critical questions a mold builder should ask before sending a mold out for service:

Polishing

- How much material did you leave?

- Where are you finishing?

- What is the required finish and what does that finish mean to you?

- What areas have some leeway (e.g., do all cutter marks need to be removed)?

- What is the part making?

- Are parting lines finished?

- Does everything need to be sharp?

- What are the critical dimensions?

- What is more important: finish or size?

Seasoned professionals work together with next-generation workers to meet customer deadlines and quality requirements like for this hot runner repair job.

Hot Runner

- Does the job require the entire hot half or hot half components only (manifolds, drops, plates)?

- Are there any flow channel blockages?

- Is the system flooded or leaked? Is this routine maintenance?

- What is the resin and process temperature?

- Are all the heaters working properly?

- Are there any problems with temperature control?

- Will the manifold or drop heaters require rewiring?

- Will you need new thermocouples?

- Are any parts/components damaged?

- Do you want components replaced?

- Do you have spare parts?

Mold Maintenance

- What is the size of the mold?

- How many cavities are having an issue?

- When will the tool be ready to go out?

- When do you need it back?

- Do you have any pictures of the tool and/or the damaged area?

- Do you have any last shots or piece parts?

- Do you have drawings, prints or files?

Laser Welding

- How much weld do you need finished when you can’t see the physical damage and you need to build up a shutoff surface?

- What is the base material?

- Does the order need to be picked up or is it being shipped?

- Was a direct contact provided for the person responsible for answering questions?

- What amount of buildup is needed when finished machining?

- What location needs welding?

- Is blending and polishing to remove the weld needed?

Laser Engraving

- What material is it?

- Do you have a file?

- What is the depth of engraving (is it critical)?

- Will additional stock be removed?

- Do we need to go deeper than the print calls?

Teamwork is vital to getting a job done right. Here, Founder John Demakis gets hands-on when a job requires his experience.

When looking for that service provider to add to your network, consider a team of experienced polishers, mold builders, laser welders, hot runner manifold technicians and laser engravers who can share their knowledge and skillset under one roof to provide assistance with any job.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Determination and Skill Save Critical Micro-Mold Cavity

Team 1 Plastics Inc. found a new supplier “soul mate” in Alliance Specialties and Laser Sales (Wauconda, Illinois), which displayed a commitment to, and the skills for, a successful micro-mold cavity repair solution.

Read MoreMaking Moldmaking Conversation

MoldMaking Technology on The Manufacturing Alliance podcast have a little fun while showcasing some familiar faces yet untold facets of the businesses, technology and lives of mold builders across North America helping to build this industry.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More