Finding the Right ERP Solution for Your ETO Shop

The engineer to order environment cannot be managed successfully without serious consideration of the technology needed to support this very different manufacturing process.

Almost a decade ago, it was reported that more than one-third of all mold manufacturers are custom shops, producing one-of-a-kind, unique products. We also noted that these special engineer-to-order (ETO) manufacturers were the most vulnerable in surviving due to thin margins and specific process challenges. Now 10 years later, two-thirds of all mold manufacturers fit the ETO description and are equally (or more) precarious.

Replicating the survey methodology conducted in early 2002, data among the 300 companies surveyed revealed that the current attrition rate of ETO senior operations managers' was double in the last 18 months compared to repetitive manufacturers. What has not changed in the ETO moldmaking environment is the heightened likelihood of ineffective material ordering and handling and dramatic cost overruns. What remained consistent a decade later are greater variables and less predictability in the ETO manufacturing process. Operations managers are still blamed for these problems.

Manufacturing companies face increasing pressure to increase market share and improve profit margins. According to Kevin Prouty, Research Director, Enterprise Applications, Aberdeen Group, in 2011 “best-in-class” companies feel significant pressure to “Reduce costs, find ways to make it easier for their customers to do business with them, manage growth expectations, address interoperability issues between multiple organizations and deal with global market pressures.”

Prouty insists that the strategies and actions used to address these business pressures vary, but successful companies “streamline and accelerate processes to improve efficiency and productivity, standardize business processes, provide visibility across the organization, modernize their technology infrastructure and applications, and optimize their current capacity.”

Ten years ago we examined technology solutions that could help ease these challenges. There were few choices. Today there are more technology solution providers to consider.

Unique Challenges and Technology Solutions

Many mold manufacturers are currently delivering a hybrid of custom and standard products; they have learned along the way how to deal with some of the additional complexities of custom manufacturing.

Companies structured only for repetitive, discrete products, rarely have the expertise or organizational structure to make the hybrid transition without significant time, investment or expertise. The move to the ETO world cannot be made without serious consideration of the technology needed to support this very different manufacturing process. All the advantages of ETO manufacturing can be lost without the correct technology and expertise to support this business model.

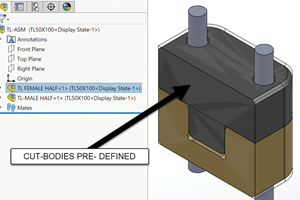

Some of the survey respondents identified specific differences in adapting to the Engineer to Order environment noting that most jobs are project-based, larger scale and a longer duration. Extensive estimation and technical quoting require many iterations, multiple passes for customer review and acceptance, as well as contract-based inventory management, plan by project, stock for project, purchase to product, stock dedicated material to projects.

Unlike consistent, repetitive and uniform molds with sku’s, ETO molds often include significant engineering changes and variations during the project lifecycle. Comprehensive project costing at actual cost—including fees, expenses, labor, material and miscellaneous charges makes matters even more complex.

Moldmakers must measure financial performance and cost variances based on the original estimate as well as integrate with MS Project, work breakdown structures, Gantt Charts, resource allocations, percent of completion and earned value analysis.

Billing in the ETO process requires that manufacturers ship and invoice all stages of project including Work in Progress. This mandates that companies can handle prepayments and deposits, milestone, progress, POC and Earned Value billing.

Moldmakers often find profitability involves warranty and service after sale or complete product lifecycle management—including as-built and as-maintained BOMs, spares and replacement parts, repairs and/or field service.

ERP

Most standard off-the-shelf enterprise resource planning (ERP) solutions lack the operational requirements of ETO manufacturing. With the proper expertise in the ETO environment, there is actually an opportunity to upgrade and improve the technology supporting the transition to an ETO hybrid or ETO-exclusive environment.

Improving the time recording process is vital for ETO manufacturers due to the hundreds (or thousands) of engineering changes made during the manufacturing process. Engineering, design and development time must be effectively and efficiently captured. It must also be accurately applied to projects that will ultimately be billed to customers.

Perhaps the reason so many ETO operations managers find jobs jeopardized is that ETO manufacturing profit margins can be consumed by the overhead and effort associated with item and BOM maintenance during the estimating and technical quote phase. It is critical that these costs are minimized and improve the conversion from quote to a billable project. Fully integrating custom engineering and project manufacturing with company financials is critical. Technology solutions for the ETO process must provide analytical data allowing senior management to appropriately monitor the impact of the business.

Other technology solutions include Cloud- or SaaS-based models, from major players and niche providers. However, technology and viability still remain major concerns as smaller, niche ETO vendors, lose their ability to compete or are gobbled up by larger vendors who may not have the same commitment, knowledge or expertise in the ETO market.

The potential for continued consolidation in the ERP market may further limit the available choices for ETO-specific solutions. Technology innovation will continue to drive change, while features like mobile technology and automation present huge opportunities and challenges.

Even with the development of many “standard” features for the ETO market, many software providers still do not behave like ETO manufacturers. Sometimes their network of delivery partners are not equipped to handle the implementation of the ERP solution with unique, customer-tailored processes and screens that actually fit the real-world requirements of the ETO environment.

The key feature of ERP for ETO today is the ability to mold and shape it—without significant additional costs—to the unique characteristics of each moldmaking project. Instead of making ETO manufacturers conform to the constraints of a business system, the key differentiators of an ETO manufacturer must be addressed and enhanced to streamline these processes. At its best, ETO ERP, provides a tool with deep core capabilities that is flexible and adaptable enough to accomplish critical tasks, delivering high value through uniquely fitted solutions.

No ERP system on the market today is designed to inherently understand the complexity of every business process out of the box. The reality is almost every custom manufacturer has some unique ETO business aspect which sets them apart in their industry. Capturing these aspects and manipulating the ETO ERP system to optimize the differentiators, provides the greatest overall benefits.

Regardless of the final technology decision, moldmakers must ensure the organization with whom they partner has many years of experience servicing the ETO market. Speak with other ETO companies that have gained the advantages of the flexibility and adaptability of a proposed technology solution and ensure the references share how the ETO ERP solution has allowed for streamlining and optimization of operations, while increasing competitive advantages and bottom-line impacts. The ERP for ETO of the future must provide a rich set of ‘standard’ features, while remaining highly flexible and adaptable to the unique business conditions every ETO manufacturer faces.

Related Content

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

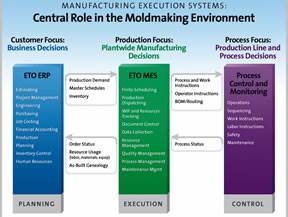

Manufacturing Execution Systems for Mold Manufacturers

A look at a system for mold manufacturers that can be used to measure and control critical production activities.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More