How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

In injection molding, we usually control the mold at a fixed temperature by making coolant continuously flow through the mold. If the coolant flow is not enough, or the coolant temperature is not as expected, the mold temperature won’t be able to keep at the designated temperature. The manufacturers of mold temperature controllers calculate the appropriate mold temperature controller specifications according to the size of the mold and the part. However, it can be a challenge for engineers and analysts using the simulation software to evaluate the performance of a mold temperature controller.

Here are a few principles for using CAE software to better evaluate the performance of mold temperature controllers.

Photo Credit, all: Moldex3D

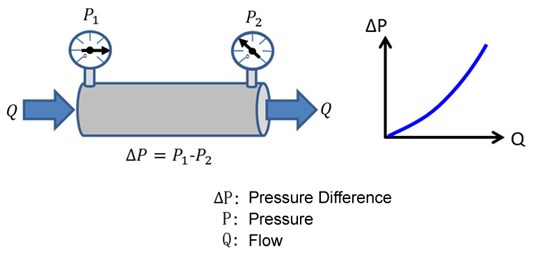

- In Moldex3D’s Flow analysis settings, users can apply two types of boundary conditions for cooling channels: flow rate and pressure. When the coolant flows through the cooling channel, the flow rate at the inlet and outlet are equal. Users only have to measure the flow rate at one side of the cooling channel, and the flow rate at the other side can be attained. So, using the flow rate as the boundary condition is easier to control. In terms of pressure, the inlet pressure is higher than the outlet pressure, and the flow is caused by this pressure difference. The default value of the outlet pressure is zero. Users only have to set the pressure boundary at the inlet, and this value will be equal to the pressure difference between the inlet and outlet. If we create a plot to show the relationship between the cooling channel flow rate and pressure, we can see that the flow rate gets larger as the pressure difference gets larger. The two parameters are approximately proportional.

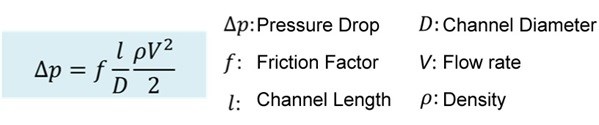

- Apart from the pressure difference, flow resistance is another factor that will affect flow. Flow resistance varies with some conditions, such as cooling channel diameters, channel length, channel wall smoothness, coolant properties and flow rate. The Darcy–Weisbach equation shows the relations between these parameters.

The Darcy-Weisbach equation showing the relations between cooling channel diameters, channel length, channel wall smoothness, coolant properties and flow rate.

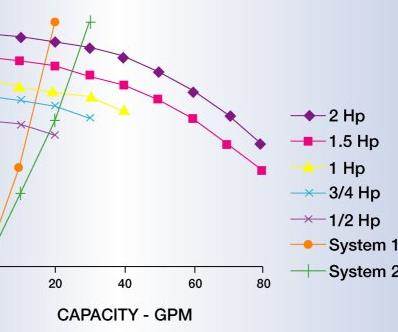

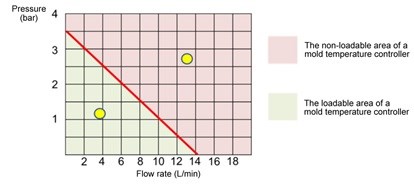

- The function of a mold temperature controller is to push the coolant to flow and stabilize the coolant temperature. The main function of the pump in the mold temperature controller is to push the coolant to flow. When the pump pressure rises, the flow rate decreases; when the flow rate increases, the pump pressure decreases. We can see the maximum flow rate and maximum pressure values on the mold temperature controller specification, but we have to note that the two conditions never exist simultaneously. We can see the mold temperature controller pressure is inversely proportional to the flow in the figure below.

Mold temperature controller pressure is inversely proportional to the flow.

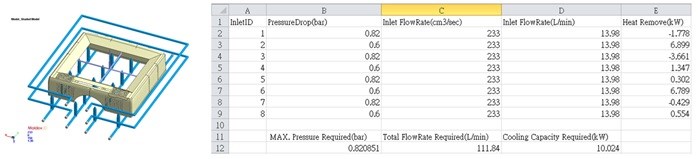

- Users can obtain the flow rate and pressure difference of every cooling channel through cooling channel analysis. The total flow rate of the cooling channels is the flow the mold temperature controller has to provide. The maximum pressure in the cooling channel is the minimum pressure the mold temperature controller has to provide. Users can enter point coordinates of the total flow rate and maximum pressure differences in the line graph. If the coordinate point is below the line, it means the mold temperature controller is able to provide enough flow rate and pressure. If the coordinate point is above the line, it means the mold temperature controller is not able to provide enough flow rate and pressure. The latest version of Moldex3D, R17, is now able to provide the data of maximum pressure drop, total flow rate and heat dissipation. Users can evaluate the mold temperature controller’s performance by adopting the pump performance curve.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Mold Cooling Optimization From a Moldmaker's Perspective

Mold cooling is the single most important factor in terms of mold productivity. Mold cooling improvements will influence cycle time and part quality - both of which will directly impact profitability.

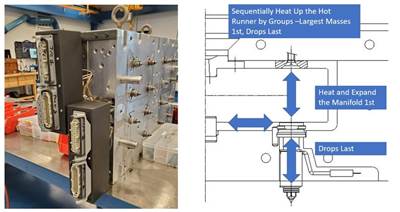

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreNew Molding Simulation Solution Enables Realization of Smart Manufacturing

EPS Flo-Tek and Moldex3D releases Moldex3D R17, the next-generation plastics molding simulation solution, helps users close gap between physical and virtual worlds.

Read More