Manufacturing Execution Systems for Mold Manufacturers

A look at a system for mold manufacturers that can be used to measure and control critical production activities.

Share

A Manufacturing Execution System (MES) is a system that mold manufacturers can use to measure and control critical production activities. Some of the benefits of MES solutions are increased traceability, productivity and quality.

Other functions served by MES solutions may include equipment tracking, product genealogy, labor tracking, inventory management, costing, electronic signature capture, defect and resolution monitoring, key performance indicator (KPI) monitoring and alarming, executive dashboards and other various reporting solutions.

MES Defined

Prior to the invention and implementation of MES, information technology tools could not provide real-time data that production managers require to make accurate and informed decisions. Mold manufacturing’s critical MES functionality includes mapping customer orders to specific production runs as well as controlling and dispatching orders; a production schedule must be based on actual (rather than projected) information about labor, material and machine productivity.

MES systems allow for the definition and enforcement of production procedures and business rules, and automatically alert production personnel to deviations from production rules. The ability to provide an integrated quality management process provides real-time feedback and automatic alerts to positively affect the utilization of specific equipment, routes, operators and material combinations for a particular work order or moldmaking project.

It is important to note that the term MES is held very loosely across different manufacturing industries such as semiconductor, process, food and beverage, and woodworking. There are idiosyncrasies of MES for mold manufacturers.

Manufacturing Execution Systems Association International is a nonprofit association representing MES software vendors and suggests, “Manufacturing execution systems deliver information that enables the optimization of production activities from order launch to finished goods. Using current and accurate data, MES guides, initiates, responds to and reports on plant activities as they occur. The resulting rapid response to changing conditions, coupled with a focus on reducing non-value-added activities, drives effective plant operations and processes. MES provides mission-critical information about production activities across the enterprise and supply chain via bidirectional communications.”

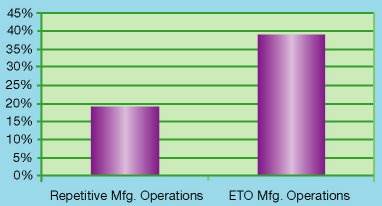

MES has many parts and can be deployed on various scales. From simple WIP (work-in-progress) tracking to a complex solution integrated throughout an enterprise that monitors the following: controlling all resources used in the manufacturing process from cradle to grave as well as critically interfacing with other enterprise systems like Enterprise Resource and Planning Systems (ERP), Product Lifecycle Management (PLM), Supervisory, Control and Data Acquisition (SCADA) solutions, and Scheduling and Planning Systems (both long-term and short-term tactical) (see Graph).

How to Identify MES for Moldmaking

According to Randy Richel, President of Trakware, “MES for moldmakers is distinct because two molds are seldom the same. Commonality in metals, processes, designs are somewhat repetitive, but variances (such as cavity and core configurations) often play a major role in production time and costs.”

Properly suited moldmaking MES technology must ideally provide the following:

- An accurate method for estimating, job costing with a closed-loop estimate to actual

- Progress reports for clients, progressive billing and shop scheduling

- Part tracking

- Shop floor data collection

- Purchasing and receiving / material management

- QA reporting

- Accounting and CAD links

Nearly 100 percent of moldmakers are ETO (engineer-to-order), which requires that MES solutions are capable of a tight integration between projected (estimated) and actual costs; engineering and production management (purchasing, job costing); and, CAD/CAM and production.

Ironically, despite the central and vital role an MES system should take in moldmaking, the way most moldmakers currently work without an MES solution includes:

1. An MRP system.

2. Estimating on a one-by-one basis, using an Excel spreadsheet.

- Using time estimates extrapolated from previous and similar jobs.

- Pre-engineering the job and using CAM-generated machine times.

3. An accounting package “altered” to suit manufacturing.

The limitations of MES not designed for the moldmaking environment have a poor allowance (if any) for job variation. They lack parametrics: the ability to adjust or change based on parameters.

The dictionary definition of a parametric equation implies that these parameters are based on coordinates: a set of mathematical equations in which coordinates of points are explicitly expressed in terms of independent parameters. Parametrics in an ETO MES solution must track parts and products that can dynamically adjust to Bills of Materials (BOMs), Bills of Labor, routings, costs, selling prices and sizes.

The most important characteristics moldmakers should consider in the selection of an MES system are suitability to the manufacturing environment; namely, customizable solutions and the ability to view the entire enterprise nature of the solution by bringing together islands of information.

![]()

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Can the Wrong ERP System Cost You Your Job?

More than one-third of all moldmaking manufacturers are custom shops, producing one-of-a-kind, unique products. Ironically, these special engineer-to-order manufacturers are the most vulnerable.

Read More