Spray Form Technology Fills the Gap in Plastic Mold Tooling

New method for producing steel yields significantly better overall tooling economy.

Process improvements in the tool steel industry have continued at a rapid pace in the last 10 years. New developments in remelting of traditionally ingot cast tool steels, and improvements in the cleanliness of high density powder metallurgical materials have been a strong focus. But while the grades produced using these technologies have filled the need of most tooling applications, it has become obvious that there is a gap created between the conventional production routes and those of powder metallurgical steels.

This gap exists in terms of actual tooling performance, and price for tooling materials. A careful evaluation of available technologies has led to the discovery of a relatively new method that enhances the performance of current conventional grades, and permits the choice of new alloy development, while being sensitive to the cost constraints of the tooling customer. This method is called spray form technology.

Spray Form Technology

Traditional casting methods include solidification times on the order of minutes or even hours. In contrast to the traditional methods, the solidification times associated with spray forming are a matter of seconds. This ensures a billet free from macro segregation and in many cases even free from micro segregation.

Spray forming is one of the most advanced methods of producing steel and requires the careful control of many interacting process parameters. However, under satisfactory spray conditions the billet geometry can be held within tight tolerances. New alloy systems can be developed to fulfill special demands as well as being able to spray billets of conventional and better established alloys.

Today, steel billets with a weight of approximately 3.5 metric tons can be delivered in the soft annealed condition. In addition, forged bars of various dimensions also can be supplied.

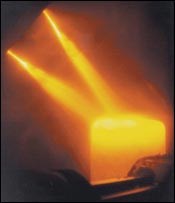

The spray formed steel is manufactured using a unique new process technology called the Osprey process (see Figure 1). The steel is melted in a crucible using two induction furnaces and is then atomized in a spray chamber under a protected atmosphere. A specially designed spray head is used to deposit semi-liquid onto a short cylindrical former, which is simultaneously rotated and slowly moved in a direction parallel to the axis of the former. By carefully controlling the movements of the former and the spray parameters, it is possible to manufacture cylindrical billets up to 550 mm in diameter and 2500 mm in length.

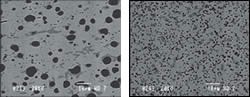

When comparing this technology to that of powder metallurgically produced tool steel, the carbide size is at least twice the diameter at 1-20 μm, predominantly 10 μm, while that of PM is 2-5 μm (see Figure 2).This larger carbide size in highly abrasive environments can be an advantage.

Spray Form Grades

The spray formed steel can be produced in different grades, which can then be normally processed by forging or hot-rolling before being machined and delivered to toolmakers for the production of tools.

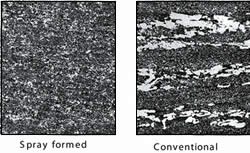

Three such grades are the focus for plastic molding applications. In one case, the technology is used to create a more uniform D2 microstructure. As shown in Figure 3, the microstructure of a conventional D2 versus a spray form D2 (a wear resistant through hardening steel) shows a much finer and uniform dispersion of carbides. The typical carbide size in D2 is 1-50 μm, predominantly 25 μm. This aids in the ductility of the material and hence better resistance to chipping and breakage.

For an even tougher, wear-resistant alloy, a high toughness spray form grade was developed. This grade has a lower carbide content than a D2 type material, and is typically used up to 58 HRC. The leaner chemistry helps to provide the ductility that this material needs to be successful in applications like screws and nozzle tips, while the carbide content gives it the wear resistance to withstand abrasive additives in the plastics.

The hardening temperature range for this grade is typically 1020 to 1050°C, (1870 to 1920°F), which is lower than other materials used for similar applications. This is a definite advantage, because distortion in longer lengths will be minimized, and the structure of the material will be optimized to help keep the tooling dimensions stable.

Chart 1 shows the improvement in wear resistance of a high toughness spray form grade versus that of a 9 percent Vanadium PM steel. For example, a high toughness spray form grade at 52 HRC has the same wear resistance as 9 percent V PM at 57 HRC. This, coupled with the better toughness in the alloy, presents a nice alternative to PM steels at a competitive price.

A third grade, a high hardness spray form grade, was developed for substantially more wear resistance than the presently used high alloyed steels. It is positioned in between higher alloyed tool steels and cemented carbide. With even more abrasive wear resistance than a PM tool steel, this grade gives a better combination of wear and chipping/cracking resistance than conventionally produced cold work tool steels and cemented carbides. And it provides these properties by being one of the lightest tool steel alloys with a density of .264 lbs/in3.

The overall comparisons of ductility versus wear resistance are shown in Graph 1.

Spray Form Technology in Action

By using the new spray formed steel in the production tools used (e.g. screws, nozzle tips, etc.), companies in the plastics industry see the tools lasting much longer. This results in significantly better overall tooling economy due to fewer renewal tool purchases, fewer tool changes due to wear and less production downtime due to maintenance operations, which in turn also leads to reduced maintenance costs.

A high toughness spray form grade has been tested at an American company in the plastics manufacturing industry. Injection molding screws of 50 to 80 mm in diameter, made of the spray formed steel were tested against screws made of the traditional steel type used previously. The test was carried out on an injection molding machine producing plastic grinding wheels out of plastic filled with abrasive silicon dioxide (SiO2) particles. Normally, the screws made of the 9 percent V PM steels only last one to two weeks before needing replacement, but with screws made of spray formed steel, the lifetime was much longer. The company has decided to replace the previously used steel with the spray formed steel and is now specifying it for their screws.

In a slightly different approach, another screw manufacturer evaluated the high toughness spray form grade and the high hardness spray form grade for screws in sizes 25 to160 mm in diameter. A high hardness spray form grade has been selected for its premium screws because it gave the best price to performance ratio. A high toughness spray form grade was chosen for intermediate requirement screws.

Conclusion

The spray form technology provides a needed alternative to conventionally produced tool steels and powder metallurgically produced products, by enhancing the capabilities of conventional tool steel grades and allowing for the development of new alloys with unique physical and mechanical properties.

Three new grades were discussed: one with the same chemistry as cold work tool steels, but with enhanced properties due to the spray form technology, and two other alloys totally re-engineered to provide unique mechanical and physical characteristics.

Related Content

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

Breaking the H-13 Stereotype For the Common Mold

A look at the new grades and steel making practices that are available to address the day-to-day issues that occur in the operation of a mold.

Read MoreCost Savings for Mold Materials: Consider the Details

Ways to reduce costs that are not related to the price per pound of the mold material.

Read MoreSpray-Formed Steels Help Moldmakers Meet New Demands

Advances in spray-formed steels help moldmakers meet increased demands on production lifetime of molds and other machine tools.

Read More