The Value of the Right Cutter Carbide Material and Coating

Consider mirror-edge geometry and carbide-grade combination heat-resistant PVD coatings when trying to solve mold machining challenges.

Choosing the correct carbide grade, cutter geometry and cutting-tool coating amid the wide variety of moldmaking materials and available cutting-tool options can be a challenging task for mold builders today. However, keeping an open dialog with your cutting-tool manufacturer will help save time and money. Plus, there are exciting developments with new carbide grades, geometries and coatings that can help solve many mold-machining pain points. Here are two examples to consider when machining aluminum and hardened-material molds.

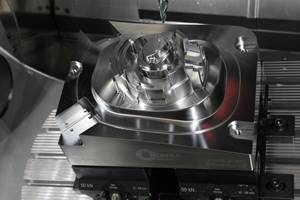

Mirror-edge geometry. Depending on the material you are cutting, the best tool for your application can reduce the cost of machining your mold by more than 500 percent. Take, for example, a mirror-edge geometry that eliminates chatter in aluminum molds. Typically, when carbide tools stick out of the spindle by more than a 3:1 length-to-diameter ratio, chatter becomes an issue, and exceeding the 3:1 ratio is the norm in mold machining.

Many machine operators choose to slow things down or are forced to take very shallow depths per pass to remedy the chatter problem. However, the mirror-edge geometry synchronizes the vibration of the end mill with the vibration of the mold. This synchronized movement eliminates the chatter, improving the finish. The other advantage that it offers is the ability to increase rpms to the maximum range of the machine, which greatly improves removal rates.

This technology can remove as much as 42 pounds of aluminum every minute. One mold builder using a mirror-edge geometry took deeper cuts with faster feed rates without chatter. As a result, the mold builder reduced a 49-minute roughing cycle time using three different tool lengths to eight minutes using only one long-length tool. The shop reduced cycle time by 525 percent.

Mirror-edge geometry can remove as much as 42 pounds of aluminum every minute.

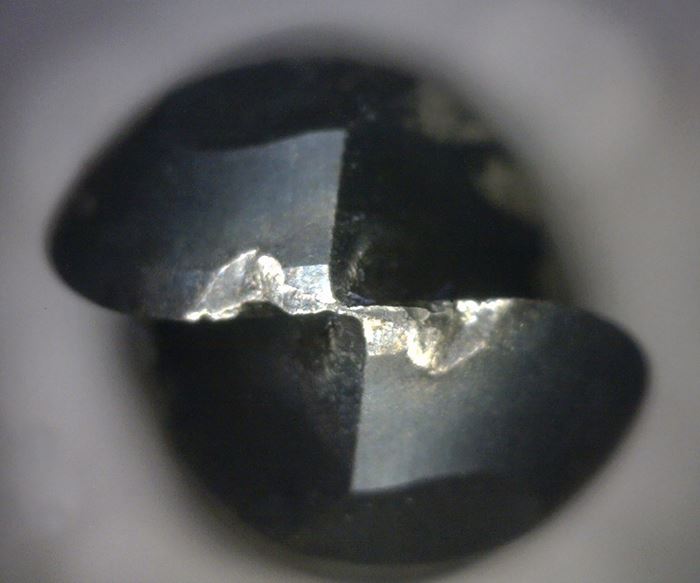

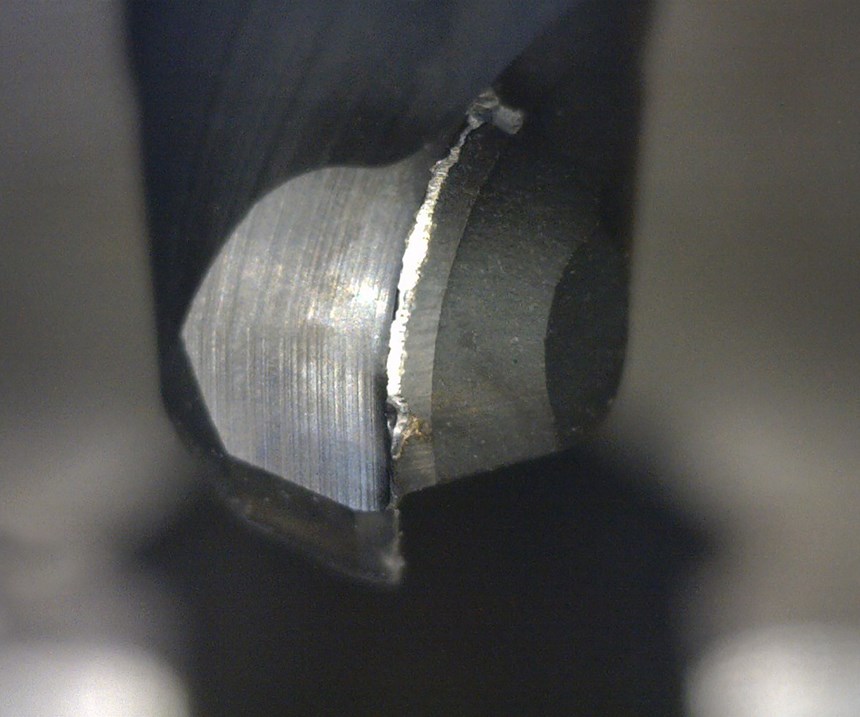

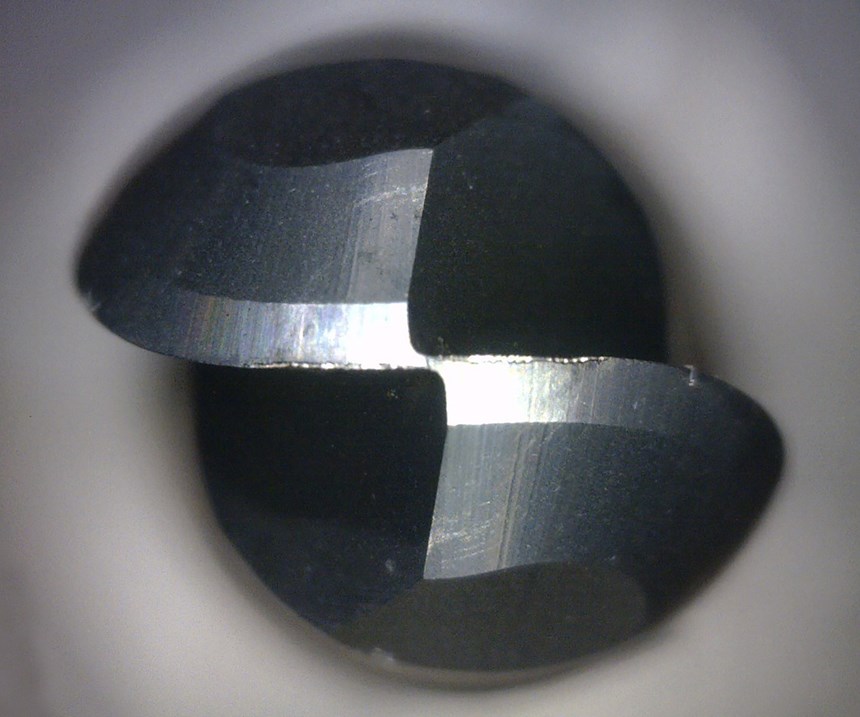

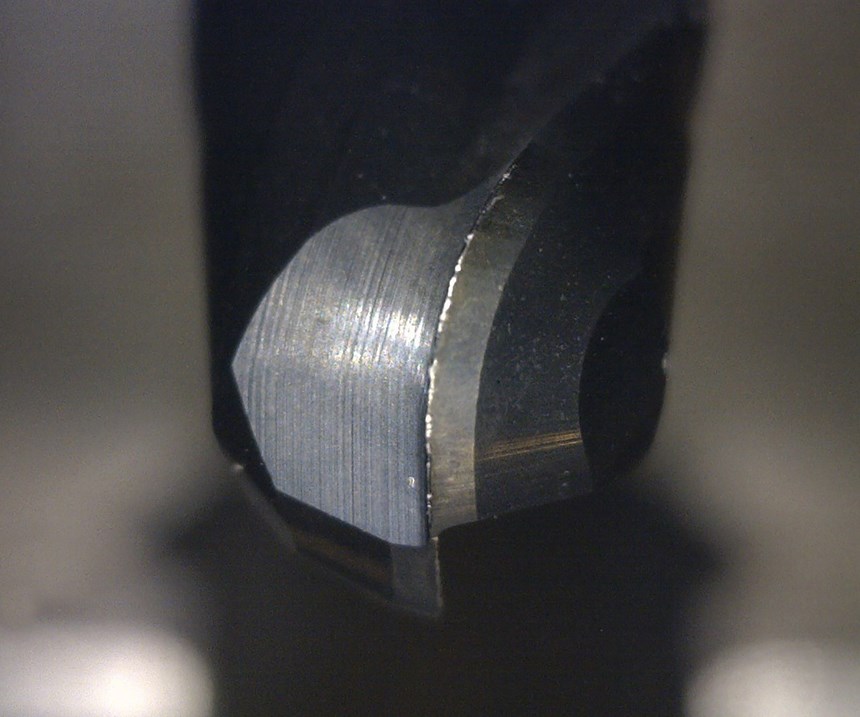

Wear-resistant carbide and heat-resistant PVD coatings. When cutting difficult, hardened materials, such as D2 at 62 HRC, getting a ball end mill to last long enough to get through the entire part can be difficult. The desire for mold-component interchangeability and ever-tightening tolerances make it extremely challenging when you are forced to change tools midway through a part. One solution is a newly developed carbide-grade combination with a heat-resistant coating. When cutting hardened materials, wear is typically the failure mode. A harder carbide grade with the same mechanical toughness will wear less than a softer carbide grade. Another mode of failure when cutting hardened parts is the high temperatures at the cut. A new specialized PVD coating acts as a heat shield during cutting, which extends cutting-tool life.

Using a carbide-grade combination with a heat-resistant coating and a specialized PVD coating can extend cutting-tool life by 450 percent and reduce wear on the ball by 909 percent. This increases 3D accuracy and allows the entire part to be completed with one tool, eliminating the potential of mismatch from the use of multiple tools.

About the Contributor

Mike MacArthur is vice president of engineering for RobbJack Corp.

Related Content

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreBuilding Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read MoreHow to Overcome Cutting Tool Vibration

Advanced indexable milling cutting tool design provides secure, predictable machining, increased metal removal rates, reduced cycle times and fast changeovers.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

Tooling Up for Challenging Cuts

To maximize quality and repeatability, you need the right cutting tools, especially in challenging applications. Here’s a guide for selecting tools for high-speed tool paths, tight areas, straight walls and graphite cutting.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)