Maintenance & Repair

The United States Microscopic Welding Association: Marrying Education and Technology

The latest in products and technology joins together with hands-on learning to keep members on top of the latest trends in microwelding..

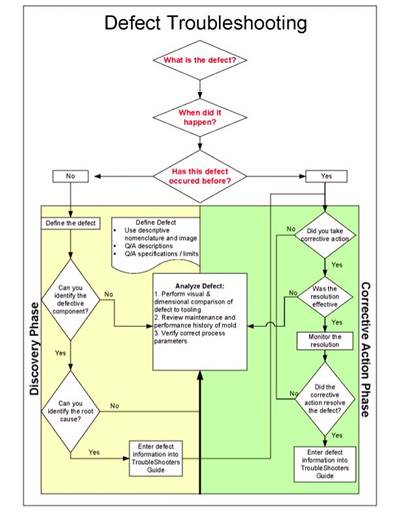

Read MoreAcross the Bench: Troubleshooting Defects: Part I

Using analytical skills based on historical mold performance and maintenance requirements, combined with mold and part defect data determines probable causes and corrective actions.

Read MoreAcross the Bench - Let's Get To Work!

The vertical and horizontal position methods used to separate mold plates each have advantages and disadvantages.

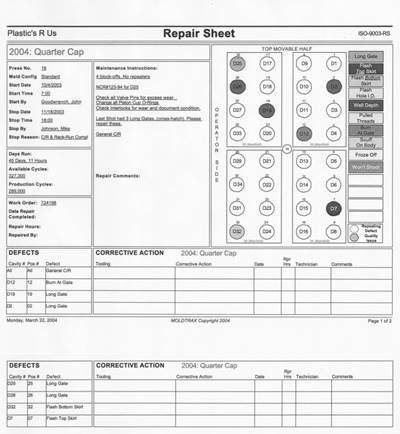

Read MoreAcross the Bench - The Plan Comes Together

The repair sheet is critical to the success of any mold repair plan.

Read MoreMinnesota Mold & Engineering Group: Strength In Numbers

Four companies unite-serving as a one-stop powerhouse for art to part and anything in-between.

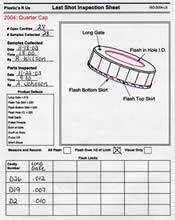

Read MoreAcross the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

Read MoreAcross the Bench: Let the Run Begin

Setup checklists, verifications and injection mold layout sheets are critical factors in the beginning of the mold process.

Read MoreTough Coatings Control and Extend Mold Life

Moldmakers can solve tough productivity problems by applying next-generation coatings.

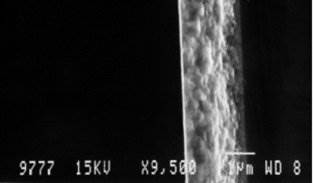

Read MoreHow to Choose the Right Welding Option

When comparing microscopic laser welding and microscopic TIG welding, both have distinct advantages and disadvantages.

Read MoreAcross the Bench: One-Man Solution

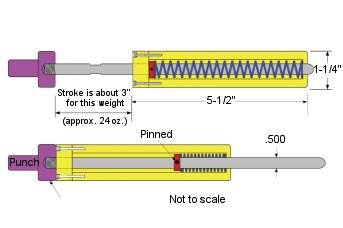

A tool specifically designed to make tooling removal a quick, safe, one-person job helps moldmakers get jobs done quickly and efficiently.

Read More