Maintenance & Repair

Part Two of a Three-Part Series Setting Up Shop

Determining repair shop space requirements.

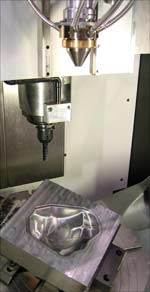

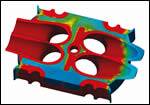

Read MorePart Two of a Two-Part Series High Power Laser Technologies And Moldmaking

Using high power laser cladding for rapid tooling and tool repair.

Read MoreHow to Select the Right Microwelding Service Provider

Teaming with the right provider can make all the difference for a mold shop.

Read MorePart One of a Three-Part Series Setting Up Shop

Just as important as creating a solid maintenance plan for molds, is the shop in which the repair takes place.

Read MoreAssembling Molds

The process of assembly is the stage during which most mistakes occur, so accurate and safe mold assembly is key.

Read MoreCleaning Molds: Part III

Ultrasonic immersion cleaning is a non-abrasive, user-friendly method that has the greatest impact on reducing cleaning time, improving mold cleaning consistency and reducing tooling damage.

Read MoreCleaning Molds: Part II

Even though hand cleaning will never be completely eliminated, ice blasting is an alternative cleaning method that can effectively reduce cleaning time and cost.

Read MoreHow to Choose the Best Welding Method for Your Mold Application

Moldmakers can save time and money on repairs by understanding the similarities and differences of conventional and micro TIG..

Read MoreCleaning Molds: Part I

Cleaning a mold is a critical part of the repair process, but many myths must be dispelled.

Read MoreTroubleshooting Defects: Part II

Repair technicians should be aware that careful handling of tooling, attention to detail and documentation keeps manifolds functioning properly and prevents costly mistakes.

Read More