Maintenance & Repair

Technology and Skill Are Keys to Mold Shop Success

In a driven and changing mold industry, a secret weapon has helped one mold shop to excel and grow.

Read MoreAcross The Bench

In this new column, real world mold maintenance issues are discussed and tips to competing in a fast-paced environment are given.

Read MoreDonna Koebel: Hands-on Leadership Gets Results

An industry veteran is properly recognized for a lifetime of hard work and success.

Read MoreA Spark of Innovation

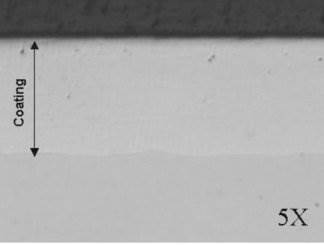

Electrospark deposition technology offers moldmakers a new process for cost-effective mold protection and repair.

Read MoreGalvanic Corrosion: Prevention Equals Preservation

By educating yourself on some of the common causes of galvanic corrosion, you may save yourself from costly mold repair and rework in the future.

Read MoreLaser Weld Repair of Molds

A nuclear weapons welding process is used to repair molds for the plastic injection mold industry.

Read MoreOptions for Restoring Molds

When a mold needs to be restored, moldmakers can turn to several different welding methods to fix the problem.

Read MoreMold Preservation and Maintenance for Ultimate Productivity

Making a mold last with as little downtime as possible is the ultimate goal of a plastic molding manager. By taking some early, preventive steps, moldmakers can extend the life of the mold and save money in the long run.

Read MoreMicro Welding: Applications Beyond Mold Repair

Moldmakers are discovering that micro welding can not only repair molds, but it also can be used as an alternative to many production processes.

Read MoreKing Systems, Plastics Technology Division - Developing A Competitive Edge Never Ends

By investing in both technology and employee skills, King Systems, Plastics Technology Division, combines the customer service advantages of a small-sized moldmaker with the cutting-edge skills needed to succeed.

Read More