Maintain

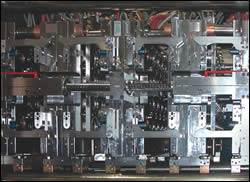

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

Read More3-D, Non-Contact Scanning for Inspection: Info for Moldmakers

Understanding the differences and similarities between CMM and 3-D scanning allows moldmakers to adapt to, apply and leverage 3-D scanning technology within their shop environment.

Read MoreWhite-Light Scanning Validates Faster, Better Processes for Molded Auto Interior Trim at Eifel Inc.

The use of white-light scanning and photogrammetry ensures accuracy of tool building programs.

Read MoreThe Tool of Choice for Mold Repair

Manual laser micro-welding systems are an alternative to traditional microscope GTA welding.

Read MorePart Two of a Two-Part Series Optimizing Mold Performance And Maintenance Efficiency

The last three steps of a six-step process for strategizing for improvement in shop operations when it comes to how we maintain molds.

Read MoreGuidelines to Put Your Production Process on the Profitability Track

A top-down commitment to investigate new options for molding materials, release agents, training techniques and equipment is critical to reduce mold downtime.

Read MoreThe Moldmaker’s Role in Controlling the Molding Process

How the toolmaker/mold designer can make the best choices when it comes to in-mold cavity sensing and control; how to do a good installation; basic functionality of the sensors; and, post installation care.

Read MoreHow to Increase Polishing Efficiencies

A concurrent approach to polishing increases the man-and-machine efficiency while streamlining workflow to help attain ever-decreasing leadtimes.

Read More“Top Secret”: How to Protect Your Mold: Top Finish, Dims and Integrity

Mold coating challenges and solutions for those working within the aerospace industry.

Read MorePart One of a Two-Part Series Optimizing Mold Performance And Maintenance Efficiency

The first three steps of a six-step process for strategizing for improvement in shop operations when it comes to how we maintain molds.

Read More