Maintain

Improve Input Quality with the Right Tool Inspection and Monitoring System

Integrating efficient tool inspection before and after the cut with optimized tool performance in the cut improves mold manufacture’s efficiency and profitability.

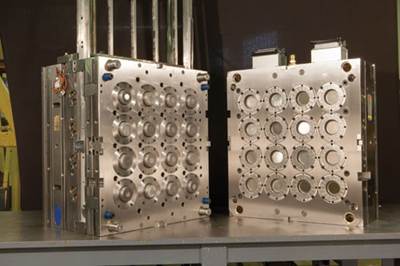

Read MoreInspection/Measurement Advances Yield Better Molds Faster

A roundtable discussion of the latest trends and developments in mold inspection and measurement technology highlights the cycle time reduction, accuracy improvement and cost decrease benefits.

Read MoreHelp Your Customers Reduce the Cost of Making Plastic Parts

How to take advantage of the properties of DLC coatings to design better molds and improve cycle times.

Read MoreInspecting Complex Product Profiles

Using metrology software and a portable CMM, mold manufacturers can efficiently handle exceedingly complex surface profile requirements.

WatchKeeping Molds Running

Technology advancements encourage moldmakers to think about surface treatment, mold maintenance and repair issues earlier in the mold build process to obtain better mold performance and life.

WatchCleaning Intricate Molds

A look at non-destructive cleaning processes for complex molds that require the removal of tenacious surface contamination to ensure surface quality and longevity of precision mold and molded part surfaces.

Read MoreTraining for More Efficient Cold Runner System Design

“The training I received from Beaumont taught me how to evaluate different runner design options for a given mold.”

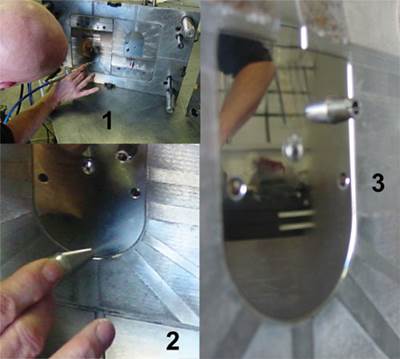

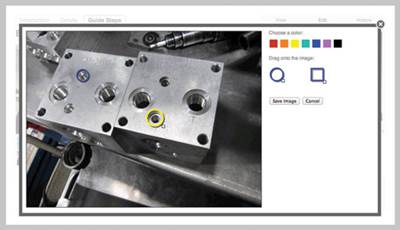

Read MoreHow to Ensure Quick, Correct Mold Maintenance

Regular cleaning and proper maintenance are key to sustaining the life of a mold.

Read MorePrecision Mold Shop Doubles EDM Capacity and Triples EDM Output

Janler’s business philosophy centers on “running the operation as a business, not a shop.

Read MoreCase Study: Mold Maintenance & Repair

Certified Mold Maintenance System Completes Service Offerings

Read More