Training for More Efficient Cold Runner System Design

“The training I received from Beaumont taught me how to evaluate different runner design options for a given mold.”

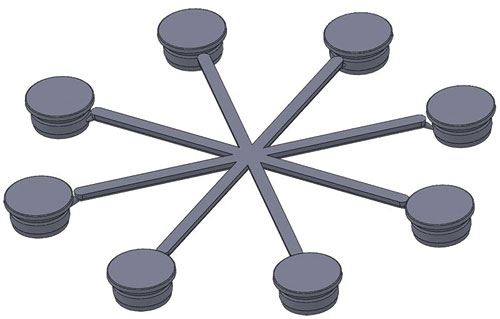

Caplugs (Buffalo, NY)—a manufacturer of protection closures that are used in a variety of industries to keep items protected during shipment and storage—has been relying on the same spoke-style runner system for many of its injection-molded plastic parts. When one of the company’s design engineers attended a Plastics Professional Training Course presented by Beaumont Technologies, Inc. (Erie, PA) and used his newfound knowledge to design a new, more efficient runner system, the results were faster production and reduced waste—all without sacrificing product quality.

Design Engineer Don Makowski has more than 24 years of plastics experience under his belt. As a member of Beaumont’s Plastic Professional Membership (PPM) Program (see PPM Specifics Sidebar), he asked his management team if he could apply some of the company’s PPM points toward attending a plastics training course at Beaumont Technologies. Little did he know how quickly this knowledge would come in handy when he implemented a new runner design for a mold used to produce plastic test vial lids with an annual volume of 300,000 parts.

Training Background

Beaumont Technologies, Inc. was originally founded in 1998 to commercialize a new plastic melt conditioning technology called MeltFlipper®—invented and developed by John Beaumont. Over the years, the company evolved into offering more product and service offerings, including consulting services and training seminars. According to David Hoffman, Beaumont’s Senior Instructor & Training Development Manager, in 2011 the company made a decision to make training and education a main focus of the company. Beaumont built a training room at company headquarters and Hoffman put together a series of educational training seminars.

Hoffman notes there are several reasons the company developed these courses. “It seems that people have stopped thinking and they just want a written procedure that tells them what to do,” he states. “They no longer question those procedures to understand what they are doing, why they are doing it, and if it should be done a different way. Simply put, too much ‘follow the leader’ mentality.”

Secondly, the company believes that there are a number of molding myths in the industry that develop because of someone's explanation of what they saw or have always done. “Often those explanations have no scientific foundation, and when tested they can sometimes fall apart,” Hoffman comments. “For example, everyone has a different theory on how to size a cold runner system. In one of our courses we explore up to six different approaches to size a runner for the same mold. We go over the theories of each method and then test and evaluate them—both good and bad features—to see if the theories are correct. And if they are correct, are those theories even important to the part? Again, rather than a person/company just doing what they have always done, we are trying to get them to think outside the box from the plastic's perspective to make better decisions based on facts, not habits.”

Beaumont also wanted to emphasize the educational focus on understanding plastic flow and part/mold design strategies, instead of offering more process training already available through several sources in the industry. Hoffman states, “We certainly understand and talk about process setup, but we focus more on how a given setup affects the plastic and the molded part. I was once talking to a quality consultant to the injection molding industry and I was showing her how to relate part quality to ‘flow groups’ within the mold. She said that I have totally changed her way of thinking. She never considered what happens to the plastic as it flows as a source of variation in part quality. She, and the majority of our industry, always wants to jump into changing the process or mold steel as a solution—rather than understanding what is happening to the plastic as it flows into the mold, which may ultimately lead them down a different path to a solution.”

Finally, Hoffman notes these seminars address the “huge” communications gap that exists between processors, quality personnel and moldmakers. “They all have their specific job function and they are good at it,” he says. “But, those three key job functions have one thing in common—plastic flow. Plastic flow affects the mold design and manufacturing, the process and the resultant part quality. But all too often those departments are coming at a problem from three different angles.” Hoffman believes if the seminars can get all three departments talking the same language, from the same perspective, then the communications will open up, the “finger pointing” blame games will be reduced—resulting in increased success for the company.”

Beaumont holds its training courses several times a month, and can hold a maximum of 20 people in each class. Currently Hoffman is working on developing a new course that focuses on educating moldmakers and designers on plastic flow and the impact the mold design and manufacturing process has on the process and molded part quality.”

Rethinking the Process

Having previously attended Seminars 1 (Optimizing Mold Start-up, Debug and Qualification) and 4 (Understanding Shrink and Warp for Successful Injection Molding), Makowski attended Seminar 2: Design Strategies for Engineering Hot and Cold Runner Systems. Not only did this seminar augment his knowledge of plastic rheology, it taught him how to think from the plastic’s perspective—using a newfound economical mindset to evaluate different runner layouts and runner sizing techniques to select the most efficient design option for a given part.

In Seminar 2, discussion delves into the characteristics of plastic flow, with plastics categorized as non-Newtonian materials that flow in a laminar condition versus a turbulent pattern, Makowski explains. In addition, discussion focuses on different runner system designs, including the spoke-style system familiar to both Makowski and Caplugs.

“Learning that plastic is laminar flowing really changed my thought pattern as to how plastic flows inside of a mold,” he states. “At first, I didn't think plastic flow was a big deal [to consider] in the simple [spoke-style] runner. The training I received from Beaumont taught me how to evaluate different runner design options for a given mold.”

For this particular project, Makowski incorporated concepts emphasized in the training, questioning “why do we do what we do” and “is there a better way?” Makowski questioned if using his company’s traditional spoke-style runner system would be best suited for his project.

By digging a little deeper, he asked Caplugs process technicians about the molds built with the spoke-style runner and found out that there were often reoccurring problems with this design—including: long cycle times due to excess material at the base of the sprue and excessive regrind—all of which were costing Caplugs money.

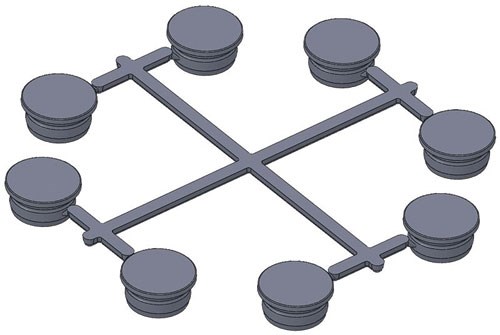

Relying on the training, Makowski devised a plan to produce a more efficient runner design. He revised the design (named the XT runner) to reduce the volume of material near the base of the sprue, which ultimately cut the cycle time by two seconds. In doing this, he was also able to reduce the runner volume by 64 percent for additional annual cost savings.

“Beaumont’s Training seminar was a catalyst that helped me to reevaluate and rethink the way that the company was molding our parts,” Makowski notes. “Prior to the seminar, Caplugs had just never changed [or thought about changing] the design of the runner [nor thought about] the impact it would have on our bottom line.”

Building a Better Mold

“Most designers, including myself, try to minimize the runner volume to save material,” Makowski elaborates. “We use the shortest distance between two points rule, but that is not the best way to approach it. I learned that balance in a runner is extremely important and the flow properties of plastic in the runner directly affect the end product—as far as warp and shrinkage are concerned. The goal is to have all the parts in a multi-cavity mold come out the same. This training broke down the characteristics of material flow, allowing me to design a better mold.”

With the cost savings seen from attending Beaumont’s training seminars, Caplugs has sent other employees to Beaumont for education and training. "In order to move into the future of plastic engineering, we need to rid ourselves of plastic molding myths and stand solidly on science,” Makowski concludes. "The science behind Beaumont’s seminars proves theories, taking the guesswork out of [understanding] how material flows. Once a designer has that understanding, he can make better informed decisions that can greatly improve designs—and avoid surprises.”

For More Information

Caplugs / (716) 876-9855

don.makowski@caplugs.com / caplugs.com

Related Content

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreHow to Foster Innovation Through a Culture of Education, Mentoring

Dynamic Tool Corp. shares its strategy for building a team with the right attitude and aptitude to deliver innovation that meets customer expectations.

Read MoreRead Next

The Real Cause of Multi-Cavity Mold Imbalances

A lesson on shear induced melt variations ends some confusion regarding balancing runner systems for multi-cavity molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More