Maintain

Five Steps to Polish an Aluminum Mold

In time and with practice, each polisher will develop his or her own tricks and short cuts.

Read MoreNyproMold Adds CT Scanning to Its Metrology Capabilities

NyproMold (Clinton, MA) highlighted its use of CT scanning as it adds a suite of innovative services to its industrial metrology capabilities.

Read MoreChoosing and Using The Right Mold Cleaners, Part 2

Knowing the requirements of offline and online cleaners yields cleaner molds.

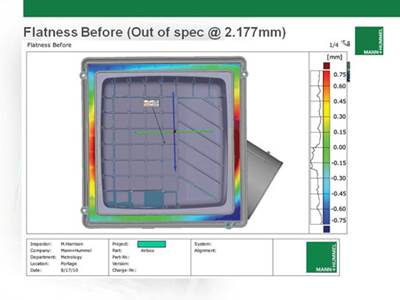

Read MoreOptimizing Mold Design with Scanning Technology

How to use scanning as a primary source of data collection.

Read MoreThermography: From Benchmark to Diagnostic Tool

It all starts with a part. There’s a problem. Whether it’s a cosmetic appearance issue, or perhaps a dimension out of tolerance it’s relatively easy to identify if there’s a problem. However, a diagnosis based on that same visual observation will also likely not identify the root cause.

Read MoreReduce Tooling Costs and Time with Laser Scanning

Aircraft Technologies, Inc. (San Antonio, TX)—a leading manufacturer of toilets for corporate jets—saved $20,000 and four weeks in reduced tooling costs/time for a new model by utilizing NVision’s (Coppell, TX) laser scanning and engineering services.

Read MoreSelective Plating of Mold Surfaces Extends Life and Reduces Repair Costs

Wear and tear on molds and the need for repairs are a regular cost of doing business for plastic and metal molders. However, costs can be drastically reduced through selective plating without removing the tooling from a machine.

Read MoreCorrosion Control: A Guide to Proper Mold Care

If you have not set up a proactive mold maintenance program, your facility runs efficiently only until the next major problem or repair.

Read MoreA Simple Way to Improve Communication with the Shop Floor

Generating set-up sheets, in-process inspection instructions and other documentation from simulated in-process machined features improves communication, saves time and increases accuracy.

Read More