Machining

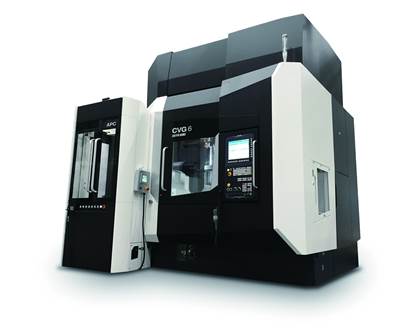

Pallet Changer Increases Productivity of Grinder by Improving Spindle Runtime

The CVG series vertical universal cylindrical grinding machine parts can be loaded onto a fixture outside of the machine while the machine is running.

Read MoreHeavy-Duty Vertical Turning Center Has Optional ATC for Increased Versatility

The Puma V3800 from Doosan Machine Tools is a new generation vertical turning center with an ATC that supports Capto C6 tooling and is available for all 12 stations of the turret.

Read MoreTechnology Tuesday: A Mix of Machining Products

Cruise through this week’s Technology Tuesday slideshow to see the latest products in machining.

Read MoreMachining Centers Designed for Complex Parts and Tough Materials

Kitmura introduces the Mycenter-HX250iG and Mycenter-HX500iG#50.

Read MoreNew Five-Axis Machining Giant Hits the U.S. to Tackle Large Machining Projects

Baker Industries installs an Emco Mecof PowerMill five-axis machining center, which is the largest and most versatile milling center in the Midwest Region and the first of its kind to enter the United States, to expand its capacity to service OEM and Tier 1 customers’ largest machining projects.

WatchCNC Gives Moldmaker Greater Reach for Large, Contoured Molds

When building molds ranging in size from 150–5,000 tons, it is important to have CNC equipment that provides both the capacity and the capabilities to achieve accurate, efficient machining on a wide variety of jobs.

Read MoreOrderfox.com Launches US Site

Orderfox.com now provides a localized website to increase ease-of-use for U.S. moldmakers looking to advertise or hire CNC manufacturing services.

Read MoreTurning Center Has Stiffness and Rigidity for Heavy Cutting

The SL8-II has robust roller guideways and six roller bearings for accuracy and heavy cutting.

Read MoreTake a Look Inside Deep Hole Drilling

Do I have your attention with this shot? It’s the inside of a gun barrel. What does that have to do with moldmaking? More than you think when it comes to deep hole drilling your waterlines, cross hole drilling, and deep pockets at compound angles, and on one machine instead of three—boring, five-axis machining and deep hole drilling in one accurate yet approachable machine.

Read MoreLessons Learned in Deep Hole Drilling

Of course when it comes to deep hole drilling, the tooling, the fixturing and the automation are all essential, but the part that caught my attention during a recent UNISIG event was the focus on mold-specific industry solutions, especially its USC-M series machines that allow multiple operations to be performed on all workpiece sides with one setup.

Read More