Leadership

Data Capture Software Maximizes Shop Floor Productivity

A new software system delivers accurate, up-to-the-minute information, bridging the gap between the shop floor and management.

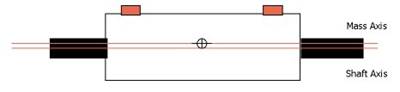

Read MoreBalancing Considerations for High-Speed Machining

Many moldmakers utilize high-speed machining in their shops today, making balancing of the tool and toolholders a priority to preserve the integrity of the work and protect the investment in the equipment.

Read MoreHow Lean Manufacturing Can Help Your Mold Shop

Rations, a moldmaker stands to save significant money in the long run by incorporating lean manufacturing into daily operations.

Read MoreData Analysis Links Design With Manufacturability

New advancements in coordinate measuring machines give moldmakers a new tool in improving operations.

Read MoreSoftware Package Increases Solid Modeling Capabilities

Moldmaker streamlines its operations with new software - cutting design time in half.

Read MoreDon't Waste Your Energy!

Learning to manage your energy systems efficiently will decrease energy costs and increase your bottom line.

Read MorePart 2: New Tool Concepts for Machining Dies and Molds

The use of multifunction inserts is a significant geometrical development - making it possible to machine various operations with a single insert.

Read MoreNew Tool Concepts for Machining Dies and Molds

The development and introduction of new insert and tool geometries for machining dies, molds and housing is an ongoing process - improving performance, tool life, surface quality and economy.

Read MoreSetting Up Shop in Mexico

Moldmakers and suppliers weigh in on the pros and cons of establishing satellite operations south of the border.

Read MoreIncrease Profitability Through Magnetic Workholding

Milling magnets offer moldmakers the convenience of fully accessible five-axis machining in one setup with the benefits of cost reduction and tolerance improvements.

Read More