Leadership

Increase Profitability Through Magnetic Workholding

Milling magnets offer moldmakers the convenience of fully accessible five-axis machining in one setup with the benefits of cost reduction and tolerance improvements.

Read MoreThe Basics of Tool Management

Proper tool management is the key to saving money - and maybe even saving your business.

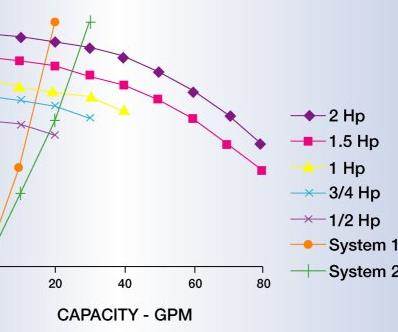

Read MoreMold Cooling Optimization From a Moldmaker's Perspective

Mold cooling is the single most important factor in terms of mold productivity. Mold cooling improvements will influence cycle time and part quality - both of which will directly impact profitability.

Read MoreThe Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.

Read MoreHow to Tackle the Labor Shortage and Training Issues

Quality management is a task that needs to be directed from the top down - with managers and supervisors ensuring that employees have the necessary skills to be productive members of the team.

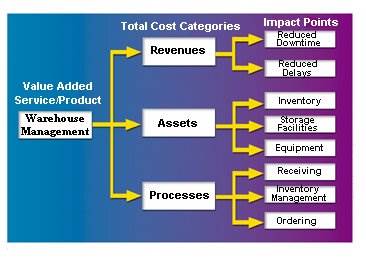

Read MoreBusy Work No More

Let an expert manage your inventory so that you can concentrate on the craft of moldmaking.

Read MoreISO 9001 - Is the Payoff Worth The Effort?

Many companies that have implemented ISO 9001 report a variety of benefits, including improved quality performance, greater operating efficiency, cost reduction, improved employee awareness and enhanced public image, among others - making ISO 9001 a sound investment.

Read MoreCAD Brings Advanced Design Tools to Development of New Starbucks Chocolates

CAD designs and rapid prototyping helped ease the design of a new chocolate product for Starbucks - and helped to bring it to market faster.

Read MoreHigh-Performance Machining - Putting It Into Practice

Most companies are looking for three basic things: to make parts faster, better and cheaper. Often, meeting these goals requires a change in process, tooling, the machine tools and/or CAM software.

Read MoreCut the Chatter - Tooling Tips to Eliminate Vibration in Cavity Milling

By learning how to eliminate vibration in cavity milling operations, a typical moldmaking shop can decrease the wear and tear on its tools, as well as boost its level of productivity.

Read More