Leadership

Moving Operations Management to the Cloud

The network of Internet servers known as “the cloud” can be a valuable resource that allows a company to be more efficient—if it is used effectively.

Read MoreUpping Your Game with Sampling

Over the years there has been a definite trend in mold manufacturers upping their "molding" game with either sampling services or full production molding capabilities. Here is one such company making the investment.

Read MoreVIDEO: The Value of Collaborating with Competitors

This story about a palletized HMC offers lessons about more than just technology. It also demonstrates the value of keeping lines of communication open with peers.

Read MoreLaser Welder Integrates Additive Process

Providing users with the option of laser powder cladding in addition to traditional laser welding is said to speed maintenance and repair operations and expand the range of available materials.

Read MoreThin Recess Injection Molding

The next time you bring that delicious fried chicken home in a pail, take a closer look at the packaging. Developed for brand owner Kentucky Fried Chicken, the 64 oz. carry-out pail uses proprietary thin-wall innovation technology from injection moldmaker StackTeck called "thin recess injection molding” (TRIM).

Read MoreAvoiding the Pitfalls of Overseas Tooling

The keys to managing offshore tooling are solid communication, an onshore team of mold experts, part samples before mold shipment and onshore molding.

Read MoreComing Back Strong

Investment in machining centers, injection molding machines and complete molds is projected to increase significantly in 2015. Our latest capital spending survey reveals the trends leading to this upswing.

Read MoreProtect Your Tooling Investment

Lower your VOC footprint, upgrade manufacturing operations and improve the surface quality of your final products with water-based mold release and cleaning.

Read MoreYour Eyes and Ears at Euromold

Here’s a sampling of the technology that caught my eye at the annual tooling, design and application development exhibition in Frankfurt, Germany.

Read MoreNozzle-tip Details Without the Effort

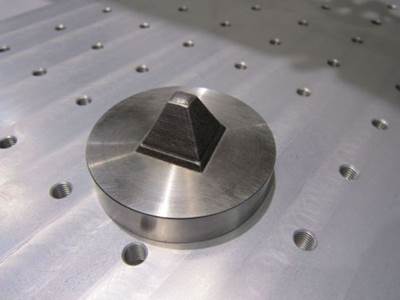

To save customers time and money, this supplier of runnerless molding systems often modifies nozzle tip geometry to suit individual applications. In some cases, this work has led to the development of new, standard tip-style offerings.

Read More