Laser Welder Integrates Additive Process

Providing users with the option of laser powder cladding in addition to traditional laser welding is said to speed maintenance and repair operations and expand the range of available materials.

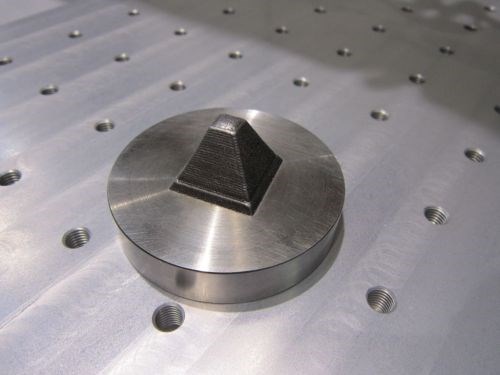

This pyramid-shaped part, which I saw at the Euromold show in November, was produced via laser powder cladding. What’s notable, however, is that the component wasn’t produced on a dedicated cladding machine, but on a laser welder—specifically, a new Diodeline machine from O.R. Laser. Featuring powder feeders aligned to deposit material directly into the diode-pumped laser’s path, these systems offer an additional option for mold repair and maintenance. According to the company, laser powder cladding suffers from none of the movement restrictions of the traditional process, in which operators must guide the weld in only one direction at a time to prevent the wire from doubling back on itself. Cladding operations are also fully programmable. Of course, the machine, shown below, can also be employed for traditional laser welding.

According to the company, one of the biggest advantages of incorporating laser powder cladding is additional material flexibility. For instance, the system can deposit high-carbon steels, aluminum, and other materials that can be difficult to draw into a wire. Lack of a wire, of course, also means precision isn’t restricted by diameter. The company adds that cladding can also be used to build mold inserts from the ground up from softer materials like beryllium copper, which can be coated for hardness later. Finally, even in traditional welding applications, the diode-pumped laser is said to provide higher energy efficiency, less maintenance and other advantages compared to nd:Yag offerings.

This machine is just one of many examples of technology that intrigued me at the Euromold show. As in recent years, additive manufacturing proved a particularly big draw, with an entire hall dedicated to that technology drawing plenty of traffic day-in and day-out. Yet, the show also offered plenty of innovations from more traditional players in the die and mold industry. Click through this picture gallery for a sampling of what caught my eye.

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

.jpg;maxWidth=300;quality=90)