Nozzle-tip Details Without the Effort

To save customers time and money, this supplier of runnerless molding systems often modifies nozzle tip geometry to suit individual applications. In some cases, this work has led to the development of new, standard tip-style offerings.

Share

Read Next

The plastic runner shown above is fed by a rather lengthy cold sprue, but it didn’t have to be. In fact, it probably shouldn’t have been.

So says Peter Rebholz, vice president of sales at Osco, a supplier of runnerless molding systems. If it were up to him, he says he’d specify a hot sprue nozzle that would reduce the length of the sprue and eliminate the need to wait for the lengthy cold sprue to cure before opening the mold and ejecting the part. With molding cycle times measured in seconds and potentially high part volumes, even the slightest savings in cycle time and material costs can add up quickly, Rebholz says.

Of course, in a retrofit application, this would lead to extra work to cut the runner detail in the nozzle's tip. Critically, however, that extra work wouldn’t fall to the customer. Rather, Osco would take on the task of machining the the runner into the tip prior to its shipping to the customer and installation in the mold.

Applications that call for putting mold details in to the nozzle tip are increasingly common for Osco, he notes, adding that the willingness to cut specific contours into tip geometry is one factor that sets the company apart. In some cases, this even leads to new additions in the company’s standard product line.

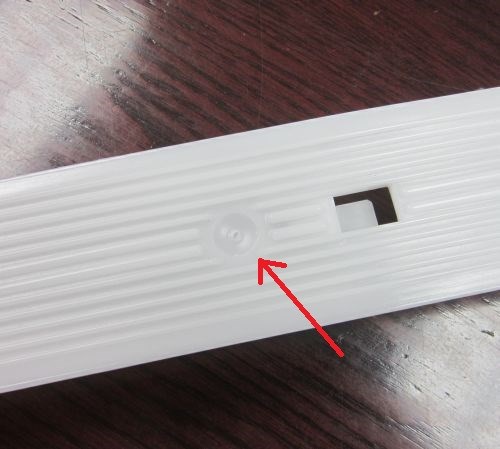

Osco’s recessed gate tip, used to create the “dimple” feature on the part shown below, is just one example of a frequently-requested modification leading to a new standard product offering. The most obvious advantage of the recessed-gate tip is that it avoids the need to for customers to machine dimple geometry themselves, whether into the mold itself or into the nozzle (the need to machine nozzles already installed in the mold can complicate the latter task). As Rebholz describes, this can be a major advantage. “Let’s say something goes wrong,” he explains. “Let’s say you get stringing or drooling, and you want to make either the gate or the dimple smaller. You would have to go and weld it back up and machine it again. Instead, you can take care of it with the standard nozzle tip.”

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.