Hot Runners

Multi-Process Disease In Hot Runner Molds

Multi-process disease is a complex interaction between the mold, the manifold, the material, the machine and the mold temperature controller.

Read MoreAchieving Cavity Balance: Another Factor for Success

A look at good and bad cavity layouts and runner designs.

Read MoreAdvancing Mold Performance Using Hot Runner Technology

A quality hot runner system is one of the more important enhancements you can incorporate into a mold to improve molded part quality, reduce production times and remain price competitive.

Read MoreHot Stuff!

Advances in valve gating technologies and improved efficiencies heat up the hot runner market in 2005.

Read MoreThe Valve Gate Advantage

Valve gate installations must be made to manufacturer specs to obtain the advantages necessary for competitive production of injection molded parts in today’s marketplace.

Read MoreMinnesota Mold & Engineering Group: Strength In Numbers

Four companies unite-serving as a one-stop powerhouse for art to part and anything in-between.

Read MoreFive-Step Process Accelerates Part-to-Production Leadtimes

With mold commissioning analysis technology and melt rotation technologies, multicavity molds can now be commissioned faster to meet the critical time-to-market timeline, while achieving cost savings and continuous improvement in all aspects of product, process and productivity.

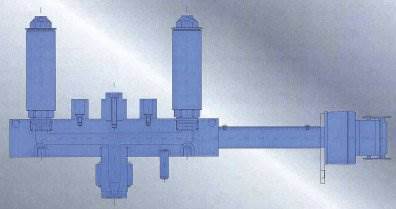

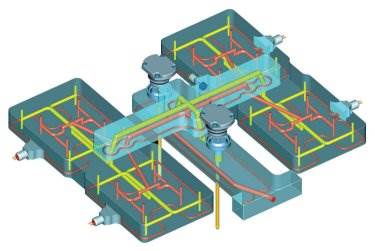

Read MoreUnitized Hot Runner Systems Reduce Errors and Save Time

Unitized and integrated hot runner systems reduce machine downtime for increased production.

Read MoreHot Runners Help the Balancing Process

When improving injection mold balancing, hot runners can assist in fine-tuning the balancing process.

Read MoreThe Value of a Well Engineered Mold Base

High-quality mold bases can help moldmakers maximize output and uptime.

Read More

.jpg;maxWidth=300;quality=90)