Hot Runners

Q&A with Robert Schad, Husky

Husky Injection Molding Systems' CEO speaks frankly about his company's success, the state of the industry and where moldmaking is headed.

Read MoreImproving a Family Molding Program

Synventive Molding Solutions joins with a leading automotive trim molder to expand the use of complex family molds for interior trim applications while providing consistent quality and a flexible process.

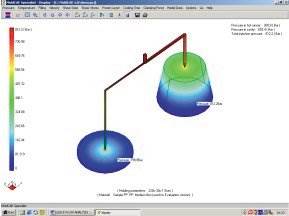

Read MoreQuick Flow Analysis of Hot Runners

Quick flow analysis technology can improve the selection, design and troubleshooting of hot runner tools.

Read MoreHow to Use Hot Runner Solutions to Help Your Customer

By offering creative, money-saving incentives to the customer, moldmakers can achieve an advantage over competitors.

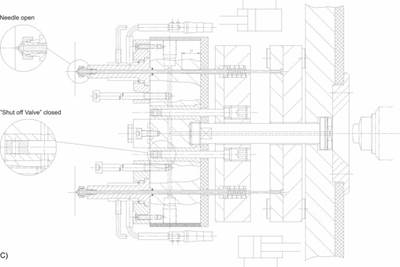

Read MoreDesigning 48 Individual Cavities in One Mold Plate

In the innovatively designed multi-cavity mold described here, every cavity has its own plunger injection system, ensuring that each cavity is filled completely and accurately with the desired amount of melt.

Read MoreHow to Design Hot Runner Plates

Moldmakers are often required to design and make hot runner plates for molds. Being aware of these best practices can make the process easier.

Read MoreBenefiting From Hot Runner Design and Reliability

Selecting a hot runner system designed with the moldmaker and end user in mind has helped a moldmaking shop remain competitive.

Read MoreHow to Work Better, Faster and Cheaper

While moldmakers may have difficulty competing with foreign markets on cheap labor, they can compete by finding new ways to build molds faster and cheaper with high-quality results.

Read More7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

Read MoreProviding the Assist

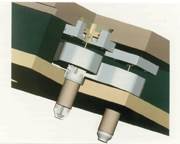

A moldmaker worked as part of a team to design and mold with a new gate-sequenced gas assist application - providing outstanding quality at a lower cost.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)