Hot Runners

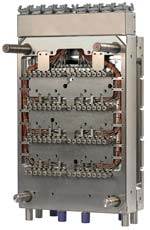

Tools with Melt Mixing Technology Help Improve Part Quality and Productivity

Delivering a hot runner mold package that ensures melt homogeneity provides mold shops with a competitive advantage.

Read MoreExtreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreSetting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read MoreMaintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

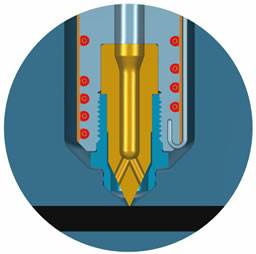

Read MoreSelecting the Right Gating Method for Your Application

Designers may select among four hot runner gating methods, each with its advantages and disadvantages.

Read MoreThree Influences that Are Critical to Mold Performance

Analysis, integrated design and value-engineering play an important role in choosing the right hot runner supplier.

Read MoreHow to Justify Your Hot Runner Purchase

Four questions to help with hot runner justification.

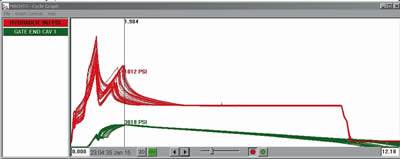

Read MorePart One of a Two-Part Series Valve Gate Sequencing Strategies

Ways to use valve gate control strategies to improve quality, efficiency and profitability

Read MoreImproving Shear-Induced Imbalance in Hot Runner Systems

Even melt distribution and balanced filling to and across all cavities while avoiding restrictive mixers is possible with hot runner manifold construction that incorporates a melt rotation design.

Read More

.jpg;maxWidth=300;quality=90)