Hot Runners

Hot Runner Stack Molds: A Great Cost-Cutting Solution

How to choose the right manifold system for your stack molds.

Read MoreElectrically Actuated Valve Gates: An Emerging Hot Runner Technology

Electrically actuated valve stems promise more control, cleaner actuation, closer pitch spacing, higher quality gates and reduced maintenance.

Read MoreStaying Competitive Using Mold Flow Analysis

The pressure on the supply chain is unrelenting for all things faster, better and cheaper. For moldmakers, getting molds built right the first time is critical to meeting these increasing demands. But how?

Read MoreHow to Evaluate Hot Runner Nozzless

The way to choose the right hot runner nozzle is to evaluate the entire molding system first.

Read MoreComplex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

Read MoreHot Runner Technology for Bio-Resins

The polylactic acid trend, material benefits and challenges to injection molding and injection mold design.

Read MoreInnovative Hot Runner Solutions for Ultra Small Parts

The injection molding of micro parts calls for innovative hot runner solutions to comply with the demands of injection molders and toolmakers.

Read MoreHot Runner Application Review Leads to Successful Processing

Successful application of a hot runner in the molding environment requires detailed analysis of gating styles, resin and molder expectations.

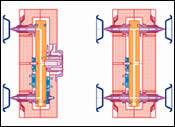

Read MoreMulti-Parting Line and Multi-Material Systems

Stack molds, co-injection, two-shot molding and their opportunities.

Read MoreCold Runner Manifold with Center Gate Provides Easy Operation, Maintenance

A cold runner manifold system for thermoset injection molds has been developed to overcome the challenges that come with using cold runners.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)