Hot Runners

Plate Fusing Technology For Designing and Building Manifolds

How plate fusing technology can benefit the mold designer/moldmaker.

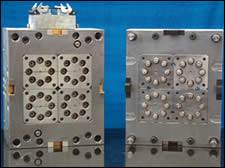

Read MoreSophisticated Hot Runner System Offers Longer Mold Life for Medical Molds

Multi-tip nozzle saves the day for high-production, high-cavitation medical molds—slashing cycle times, generating no waste, and needing minimal maintenance.

Read MoreProLink Molds: Up and Running!

This brand-new moldmaker offers molds complete with the company’s own hot runner technology to better meet its customers’ needs.

Read MoreAdvances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

Read MoreHot Runners Shrink Leadtimes, Cut Costs

Standardized hot runner system allows the moldmaker to easily configure a system in just two weeks.

Read MoreThe Moldmaker’s Role in Controlling the Molding Process

How the toolmaker/mold designer can make the best choices when it comes to in-mold cavity sensing and control; how to do a good installation; basic functionality of the sensors; and, post installation care.

Read MoreEvaporative Cooling Approach To Mold Temperature Control

This new mold temperature control technology allows tool designers to create mold designs engineered to a level previously unattainable.

Read MoreHow to Make “Quick-Turn” Your Shop’s Mantra

On top of increasing production capacity, quick delivery standards save as much as five hours per project for a manufacturer of quality “quick-turn” tooling.

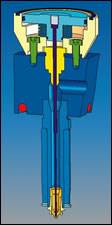

Read MoreEvaluating Gate System Designs

A hybrid gating option combines the advantages of valve gate and thermal gate systems.

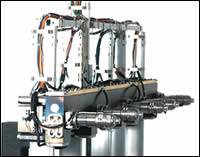

Read MoreAutomation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

Read More

.jpg;maxWidth=300;quality=90)