Hot Runner Stack Molds: A Great Cost-Cutting Solution

How to choose the right manifold system for your stack molds.

Share

Read Next

During the concept phase of a new project the option of selecting a stack mold is often overlooked because many mold designers are unfamiliar with the technology. Compared to a regular, single-face injection mold, stack molds can virtually double the output of an injection molding machine by distributing the plastic melt into two separate mold parting surfaces.

Three distinct advantages of hot runner stack mold technology are:

1. Doubled Part Output

Instead of increasing the mold size by adding more cavities, a stack mold maintains mold size and machine size by adding a second layer of cavities parallel to the first layer. The fill, pack and cooling time remain the same for a stack mold and only the mold open and mold close time will add to the cycle time.

2. Reduced Part Price

The part price is determined by the machine hour rate, which is directly related to the machine clamp tonnage. A stack mold requires only about half the clamp tonnage than a single-face mold with the same number of cavities. (e.g. An 8+8 cavity stack mold, instead of a 16-cavity single face mold design, requires a machine only half as big; smaller mold, smaller machine).

However, it has the same production output of the 16-cavity mold. A 16-cavity, single-face mold running in a 600-ton machine compared to an 8+8 cavity stack mold in a 300-ton machine would reduce the machine hour rate by 43 percent.1

3. Efficiency and Improved Automation

Stack molds can produce multi-component assemblies in one shot and in one machine using the same parameters. By comparison, single-face molds would require the production synchronization between multiple machines, complicating post-molding operations.

The Basics of the Stack Mold

The defining characteristic of a stack mold is the two mold parting surfaces or mold split lines. A stack mold does not require much more clamp force than a single-face mold because the projected part surface areas of the cavities on both sides of the center block cancel out each other’s force.

A rule of thumb for a clamp force estimate is to take the projected part surface area times the melt pressure and multiply it by a factor of 1.1. Without increasing the machine platen size, you can double the amount of cavities producing parts. Most stack molds have an equal number of the same cavities in each parting surface. For example, a 2+2 cavity grid mold with an 8+8 hot runner produces four identical parts per cycle.

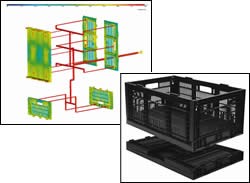

Some stack molds have different cavities in each mold parting surface and they produce a family of parts per shot, each different in shape and size, such as the collapsible crate in Figure 1a, b.

Stack molds can also handle multi-material injection—different materials such as hard/soft combination or multi-color molding. Three-level stack molds are not as common as two-level stack molds.

When the stack mold opens for the ejection of parts, both mold parting surfaces open (in most cases simultaneously) by means of a mechanical connection between the mold center block, the fixed halves of the mold and the moving half of the mold.

The mechanical connection, which moves the center block of the mold, can be:

- a rack and gear operated motion system

- a harmonic lever system

- a hydraulic push-pull system

- a helical gear system

Hot Runner System

Aside from the center block motion system, the key element of a stack mold is the hot runner system (see Figure 2). The transfer of plastic melt from the machine barrel into the mold center block has traditionally been achieved by a heated sprue bar, which leads the melt from the machine nozzle through the fixed mold half and through the first mold parting surface into the hot runner manifold, which is located in the center block of the stack mold.

The relatively simple sprue bar has the disadvantage of getting disengaged from the machine nozzle at each cycle when the mold opens for part ejection. The sprue bar may also become an obstacle at part removal, especially with robot handling equipment because it always remains inside the first mold parting surface. Consequently, better melt transfer methods into the mold center block, like the sprue-bar-less gate-to-gate transfer, have evolved.

Mold cavities, which by design, cover the center surface of the molding area do not allow a center sprue bar, so the hot runner has to bypass the melt by leading it with an off-set manifold to the outside of the mold, and from the side position through the first mold parting line into the center block for further melt distribution through the nozzles to the cavities.

Gate-to-Gate Melt Transfer

Increasingly more popular is the melt transfer through the first mold parting surface without a sprue bar because it eliminates the sprue bar as an obstacle. The basic principle of a sprue-bar-less melt transfer is a nozzle-to-nozzle melt transfer (see Figure 3).

As the mold parting surfaces close, two nozzle front ends establish a melt passage. These nozzles separate when the mold opens. A leak-free connection or seal at 2,000 bar or 30,000 psi is accomplished with the specially designed manifold system for stack molds. The front surfaces of the melt transfer nozzles contact each other at clamp force in the mold parting surface and establish a connection between the melt channels. This passage can be opened and closed through valve pin actuation during injection. During mold opening, the transfer nozzles provide a dry surface with absolutely no stringing or drooling of the melt.

A 24/7 molding operation with stack molds requires a functional melt transfer, which operates over millions of cycles.

Summary

Generally, flat parts are more suitable for stack mold consideration than are deep core parts because of the machine opening stroke and the increased mold height of a stack mold. It is also important to check the shot capacity of the machine barrel ensuring that the injection unit can supply enough melt volume cycle for cycle and for all cavities. Hot runner stack mold systems are ideal for applications in thin wall packaging, caps and closure products, containers and lids, collapsible crates, trays, panels, grills and large surface parts for appliances.

References

1 Plastics Technology, Your Business Hourly Rate Survey, May 2007; Custom Injection Molders Machine Hour Rates with Operating Profit Margins Included. http://www.ptonline.com/articles/200705bib3.html.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

Spin Stack Mold Design Results in Longer Mold Life, Higher Cycle Times

For more conventional mold manufacturers that wish to find a new niche and offer more complex molds to their customers.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More