FAQ

What Moldmakers Should Know about Cylindrical Grinding

Reducing costs, producing superior surface finishes and providing high flexibility are just a few of the advantages achieved with cylindrical grinding in mold manufacturing.

WatchHow to Move Closer to Unattended, 24/7, Lights Out Machining

A look at why there is more to lights out machining than running unattended.

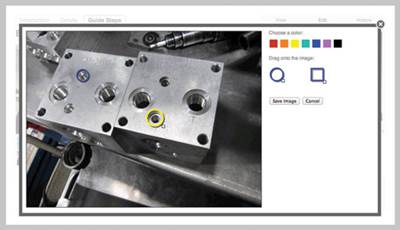

Read MoreHow to Ensure Quick, Correct Mold Maintenance

Regular cleaning and proper maintenance are key to sustaining the life of a mold.

Read MoreHow to Improve Your Business to be Best-in-Class

In today’s business climate, if mold manufacturers are not growing then they are not sustainable. To ensure your growth take a look at what you need to be concerned about as you move forward.

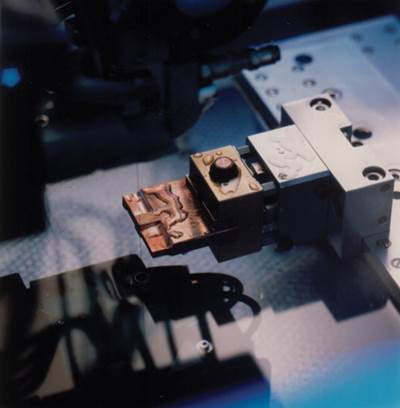

Read MoreHow to Produce Consistent, Repeatable Electrodes

When it comes to electrode production, workholding and automation technology must be accurate and consistent to ensure repeatability and reduce machining time.

Read MoreAn Innovative Approach to Employee Training

This mold manufacturer looked within its own talent pool to develop—and implement—a new apprenticeship program to address the skilled workforce challenge.

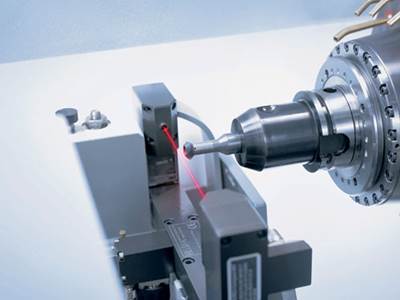

Read MoreHow to Achieve Intelligent, Automated CNC Machining

A review of the benefits of automating CNC machining by measuring and automatically changing the cutting tools as they wear during the machining process, and what a moldmaker should consider before investing in such a technology.

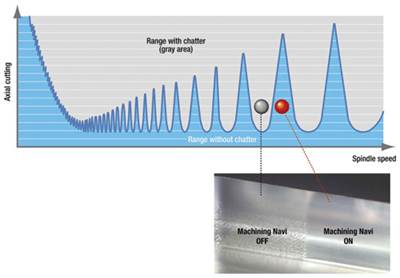

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreAutomation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

Read MoreHow to Navigate New Horizons with Waterjet

Expand capabilities and diversify customer base with waterjet technology.

Read More